1 Isingeniso

Ukuqinisekisa ukuvalwa kwezintambo ze-fiber optic isikhathi eside nokuvimbela amanzi nomswakama ukuthi kungangeni ebhokisini lekhebula noma le-junction bese konakalisa insimbi ne-fiber, okuholela ekulimaleni kwe-hydrogen, ukuphuka kwe-fiber kanye nokwehla okukhulu kokusebenza kokushisa kukagesi, izindlela ezilandelayo zivame ukusetshenziswa ukuvimbela amanzi nomswakama:

1) Ukugcwalisa ingaphakathi lekhebula ngamafutha e-thixotropic, okuhlanganisa uhlobo oluvimbela amanzi (olungenawo umoya), uhlobo lokuvuvukala kwamanzi kanye nohlobo lokukhula kokushisa njalo njalo. Lolu hlobo lwezinto luyizinto ezinamafutha, ezigcwalisa inani elikhulu, ezibiza kakhulu, kulula ukungcolisa imvelo, kunzima ukuzihlanza (ikakhulukazi lapho ikhebula lihlanganiswa nesithambisi ukuze lihlanzwe), kanye nesisindo sekhebula esisindayo kakhulu.

2) Esigxotsheni sangaphakathi nangaphandle phakathi kokusetshenziswa kwendandatho yokuvimbela amanzi enamathelayo eshisayo, le ndlela ayisebenzi kahle, inqubo eyinkimbinkimbi, abakhiqizi abambalwa kuphela abangayithola. 3) Ukusetshenziswa kokwandiswa okomile kwezinto zokuvimba amanzi (impuphu yokwandisa emunca amanzi, iteyipu yokuvimba amanzi, njll.). Le ndlela idinga ubuchwepheshe obuphezulu, ukusetshenziswa kwezinto, izindleko eziphezulu, isisindo sekhebula nakho kusinda kakhulu. Eminyakeni yamuva nje, isakhiwo "somgogodla owomile" singeniswe kukhebula le-optical, futhi sisetshenziswe kahle kwamanye amazwe, ikakhulukazi ekuxazululeni inkinga yokuzisinda okunzima kanye nenqubo yokuhlanganisa eyinkimbinkimbi yenombolo enkulu yomgogodla wekhebula le-optical inezinzuzo ezingenakuqhathaniswa. Izinto zokuvimba amanzi ezisetshenziswa kule khebula "yomgogodla owomile" yintambo yokuvimba amanzi. Intambo yokuvimba amanzi ingamunca amanzi ngokushesha futhi ivuvuke ukuze yakhe ijeli, ivimbe isikhala somsele wamanzi wekhebula, ngaleyo ndlela kufezwe injongo yokuvimba amanzi. Ngaphezu kwalokho, intambo yokuvimba amanzi ayinazo izinto ezinamafutha futhi isikhathi esidingekayo sokulungisa i-splice singancishiswa kakhulu ngaphandle kwesidingo sama-wipes, ama-solvent kanye nezihlanzi. Ukuze sithole inqubo elula, ukwakhiwa okulula, ukusebenza okuthembekile kanye nezinto zokuvimba amanzi ezingabizi kakhulu, sakha uhlobo olusha lwentambo evimba amanzi evimba amanzi evala intambo evuvukalayo.

2 Isimiso sokuvimbela amanzi kanye nezici zocingo lokuvimba amanzi

Umsebenzi wokuvimba amanzi wentambo yokuvimba amanzi ukusebenzisa umzimba oyinhloko wezintambo zokuvimba amanzi ukwakha ivolumu enkulu yejeli (ukumuncwa kwamanzi kungafinyelela izikhathi eziningi zevolumu yayo, njengoba ngomzuzu wokuqala amanzi angandiswa ngokushesha kusuka cishe ku-0.5mm kuya ku-5.0mm ububanzi), futhi amandla okugcina amanzi ejeli aqinile impela, angavimbela ngempumelelo ukukhula kwesihlahla samanzi, ngaleyo ndlela avimbele amanzi ukuthi aqhubeke nokungena nokusabalala, ukuze kufezwe inhloso yokumelana namanzi. Njengoba ikhebula le-fiber optic kumele limelane nezimo ezahlukahlukene zemvelo ngesikhathi sokukhiqiza, ukuhlolwa, ukuthuthwa, ukugcinwa kanye nokusetshenziswa, intambo yokuvimba amanzi kumele ibe nezici ezilandelayo ezizosetshenziswa kukhebula le-fiber optic:

1) Ukubukeka okuhlanzekile, ukujiya okufanayo kanye nokuthungwa okuthambile;

2) Amandla athile okusebenza ukuze kuhlangatshezwane nezidingo zokucindezeleka lapho kwenziwa ikhebula;

3) ukuvuvukala okusheshayo, ukuqina okuhle kwamakhemikhali kanye namandla aphezulu okumunca amanzi kanye nokwakheka kwejeli;

4) Ukuqina okuhle kwamakhemikhali, akukho zingxenye ezibolayo, ukumelana namagciwane kanye nezikhunta;

5) Ukuqina okuhle kokushisa, ukumelana nesimo sezulu okuhle, okuvumelana nezimo ezahlukahlukene zokucubungula nokukhiqiza okulandelayo kanye nezindawo ezahlukahlukene zokusetshenziswa;

6) Ukuhambisana okuhle nezinye izinto zekhebula le-fiber optic.

3 Intambo engangeni manzi ekusetshenzisweni kwekhebula le-optical fiber

3.1 Ukusetshenziswa kwezintambo ezingangeni manzi ezintanjeni ze-optical fiber

Abakhiqizi bekhebula le-fibre optic bangathatha izakhiwo zekhebula ezahlukene enqubweni yokukhiqiza ukuze bahlangabezane nezidingo zabasebenzisi ngokuya ngesimo sabo sangempela kanye nezidingo zabasebenzisi:

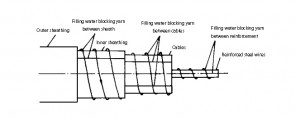

1) Ukuvimba amanzi okude kwegobolondo langaphandle ngezintambo ezivimba amanzi

Ekuvikeleni i-tape yensimbi egoqekile, i-sheath yangaphandle kumele ingangeni manzi isikhathi eside ukuze kuvinjelwe umswakama kanye nomswakama ukuthi kungangeni kukhebula noma ebhokisini lokuxhuma. Ukuze kufezwe isithiyo samanzi eside se-sheath yangaphandle, kusetshenziswa izintambo ezimbili zokuvimbela amanzi, enye yazo ibekwe ngokuhambisana ne-core yekhebula le-sheath yangaphakathi, kanti enye igoqwe i-core yekhebula endaweni ethile (8 kuya ku-15 cm), imbozwe nge-tape yensimbi egoqekile kanye ne-PE (polyethylene), ukuze intambo yokuvimbela amanzi ihlukanise igebe phakathi kwe-core yekhebula kanye ne-tape yensimbi ibe yi-compartment encane evaliwe. Intambo yokuvimbela amanzi izovuvukala futhi yakhe i-gel ngesikhathi esifushane, ivimbele amanzi ukuthi angene kukhebula futhi ivimbele amanzi ezindaweni ezimbalwa ezincane eduze kwendawo yokuphoqeka, ngaleyo ndlela kufezwe injongo yesithiyo samanzi eside, njengoba kuboniswe ku-Figure 1.

Umfanekiso 1: Ukusetshenziswa okuvamile kwentambo yokuvimba amanzi kukhebula le-optical

2) Ukuvimba amanzi okude kwengaphakathi lekhebula ngezintambo ezivimba amanziIngasetshenziswa engxenyeni engaphakathi yekhebula yezingxenye ezimbili zentambo evimba amanzi, enye isengxenyeni engaphakathi yekhebula yentambo yensimbi eqinisiwe, kusetshenziswa intambo ezimbili ezivimba amanzi, ngokuvamile intambo evimba amanzi kanye nentambo yensimbi eqinisiwe ebekwe ngokufana, enye intambo evimba amanzi ibe yi-pitch enkulu ezungezwe intambo, kukhona futhi intambo ezimbili ezivimba amanzi kanye nentambo yensimbi eqinisiwe ebekwe ngokufana, ukusetshenziswa kwentambo evimba amanzi enamandla okukhulisa ukuvimba amanzi; okwesibili kusebusweni be-casing obukhululekile, ngaphambi kokucindezela i-sheath yangaphakathi, intambo evimba amanzi njengokusetshenziswa kwentambo ye-tie, intambo ezimbili ezivimba amanzi zibe yi-pitch encane (1 ~ 2cm) ohlangothini oluphambene nxazonke, zakha i-bin encane nencane evimbayo, ukuvimbela ukungena kwamanzi, okwenziwe ngesakhiwo "se-cable core eyomile".

3.2 Ukukhethwa kwezintambo ezingangeni manzi

Ukuze kutholakale kokubili ukumelana kwamanzi okuhle kanye nokusebenza okwanelisayo kokucubungula ngomshini enqubweni yokukhiqiza ikhebula le-fiber optic, izici ezilandelayo kufanele ziqashelwe lapho kukhethwa intambo yokumelana namanzi:

1) Ubukhulu bentambo evimba amanzi

Ukuze kuqinisekiswe ukuthi ukunwetshwa kwentambo evimba amanzi kungagcwalisa igebe engxenyeni evundlile yekhebula, ukukhetha ubukhulu bentambo evimba amanzi kubalulekile, vele, lokhu kuhlobene nosayizi wesakhiwo sekhebula kanye nesilinganiso sokunwetshwa kwentambo evimba amanzi. Esakhiweni sekhebula kufanele kuncishiswe ukuba khona kwezikhala, njengokusetshenziswa kwesilinganiso esiphezulu sokunwetshwa kwentambo evimba amanzi, khona-ke ububanzi bentambo evimba amanzi bungancishiswa bube buncane kakhulu, ukuze uthole ukusebenza okuthembekile kokuvinjelwa kwamanzi, kodwa futhi nokonga izindleko.

2) Izinga lokuvuvukala kanye namandla ejeli ezintanjeni ezivimba amanzi

Ukuhlolwa kokungena kwamanzi kwe-IEC794-1-F5B kwenziwa engxenyeni ephelele yekhebula le-fiber optic. Ikholomu yamanzi engu-1m ingeziwe kusampula engu-3m yekhebula le-fiber optic, amahora angama-24 ngaphandle kokuvuza kuyafaneleka. Uma izinga lokuvuvukala kwentambo evimba amanzi lingahambisani nezinga lokungena kwamanzi, kungenzeka ukuthi amanzi adlule kusampula kungakapheli imizuzu embalwa kusukela ekuqaleni kokuhlolwa futhi intambo evimba amanzi ingakavuvukali ngokugcwele, yize ngemva kwesikhathi intambo evimba amanzi izovuvukala ngokugcwele futhi ivimbe amanzi, kodwa lokhu futhi kuyiphutha. Uma izinga lokukhula lishesha futhi amandla ejeli enganele, akwanele ukumelana nengcindezi ekhiqizwa yikholomu yamanzi engu-1m, futhi ukuvimba kwamanzi nakho kuzohluleka.

3) Ukuthamba kwentambo evimba amanzi

Njengoba ubumnene bentambo evimba amanzi bubonakala ezimpahleni zentambo, ikakhulukazi ingcindezi eseceleni, ukumelana nokushayisana, njll., umthelela usobala kakhulu, ngakho-ke kufanele uzame ukusebenzisa intambo evimba amanzi ethambile.

4) Amandla okuthamba, ukunwebeka kanye nobude bentambo evimba amanzi

Ekukhiqizweni kobude bethileyi yekhebula ngalinye, intambo evimba amanzi kufanele iqhubeke futhi ingaphazanyiswa, okudinga ukuthi intambo evimba amanzi kumele ibe namandla athile okubamba kanye nokwelulwa, ukuze kuqinisekiswe ukuthi intambo evimba amanzi ayidonswa ngesikhathi senqubo yokukhiqiza, intambo uma inwetshwa, igoba, ijika intambo evimba amanzi ayonakaliswa. Ubude bentambo evimba amanzi buxhomeke kakhulu kubude bethileyi yekhebula, ukuze kuncishiswe inani lezikhathi intambo eshintshwa ngazo ekukhiqizweni okuqhubekayo, ubude bentambo evimba amanzi bungcono.

5) Ubumuncu kanye ne-alkalinity yentambo evimba amanzi kufanele kungabi hlangothi, ngaphandle kwalokho intambo evimba amanzi izosabela nezinto zekhebula futhi ibangele i-hydrogen.

6) Ukuqina kwezintambo ezivimba amanzi

Ithebula 2: Ukuqhathaniswa kwesakhiwo esivimba amanzi sezintambo ezivimba amanzi nezinye izinto ezivimba amanzi

| Qhathanisa izinto | Ukugcwaliswa kwejeli | Indandatho yokumisa amanzi ancibilikayo ashisayo | Itheyiphu yokuvimba amanzi | Intambo yokuvimba amanzi |

| Ukumelana namanzi | Kuhle | Kuhle | Kuhle | Kuhle |

| Ukucutshungulwa | Kulula | Kuyinkimbinkimbi | Kuyinkimbinkimbi kakhulu | Kulula |

| Izakhiwo zemishini | Abafanelekile | Abafanelekile | Abafanelekile | Abafanelekile |

| Ukuthembeka kwesikhathi eside | Kuhle | Kuhle | Kuhle | Kuhle |

| Amandla okubopha emgodleni | Okuhle | Kuhle | Okuhle | Kuhle |

| Ingozi yokuxhumeka | Yebo | No | No | No |

| Imiphumela ye-oxidation | Yebo | No | No | No |

| Isinyibilikisi | Yebo | No | No | No |

| Isisindo ngeyunithi ubude bekhebula le-fibre optic | Okunzima | Ukukhanya | Kunzima kakhulu | Ukukhanya |

| Ukugeleza kwezinto ezingafuneki | Kungenzeka | No | No | No |

| Ukuhlanzeka ekukhiqizeni | Kubi | Kubi kakhulu | Kuhle | Kuhle |

| Ukuphathwa kwezinto | Izigubhu zensimbi esindayo | Kulula | Kulula | Kulula |

| Ukutshalwa kwezimali emishinini | Okukhulu | Okukhulu | Okukhulu | Okuncane |

| Izindleko zezinto ezibonakalayo | Okuphakeme | Phansi | Okuphakeme | Ngaphansi |

| Izindleko zokukhiqiza | Okuphakeme | Okuphakeme | Okuphakeme | Ngaphansi |

Ukuqina kwezintambo ezivimba amanzi kulinganiswa kakhulu ngokuqina kwesikhathi esifushane kanye nokuqina kwesikhathi eside. Ukuqina kwesikhathi esifushane kubhekwa kakhulu njengokuphakama kwezinga lokushisa lesikhathi esifushane (inqubo yokushisa ye-extrusion sheath kuze kufike ku-220 ~ 240 ° C) ezimpahleni zokuvimbela amanzi zentambo yokuvimbela amanzi kanye nezakhiwo zomshini zomthelela; ukuqina kwesikhathi eside, ikakhulukazi uma kucatshangelwa ukuguga kwesilinganiso sokwandiswa kwentambo yokuvimbela amanzi, izinga lokukhula, amandla nokuqina kwejeli, amandla okudonsa kanye nokwandiswa komthelela, intambo yokuvimbela amanzi kumele ibe sempilweni yonke yekhebula (iminyaka engu-20 ~ 30) ukumelana namanzi. Ngokufana namafutha okuvimba amanzi kanye netheyiphu yokuvimba amanzi, amandla ejeli kanye nokuqina kwentambo yokuvimbela amanzi kuyisici esibalulekile. Intambo yokuvimbela amanzi enamandla aphezulu ejeli kanye nokuqina okuhle ingagcina izakhiwo ezinhle zokuvimba amanzi isikhathi eside. Ngokuphambene nalokho, ngokwezindinganiso zezwe zaseJalimane ezifanele, ezinye izinto ngaphansi kwezimo ze-hydrolysis, ijeli izobola ibe yinto ehamba kancane kakhulu enesisindo esincane sama-molecule, futhi ngeke ifeze injongo yokumelana namanzi isikhathi eside.

3.3 Ukusetshenziswa kwezintambo ezivimba amanzi

Intambo yokuvimba amanzi njengentambo yokukhanya enhle kakhulu yokuvimba amanzi, ithatha indawo ye-oyili paste, indandatho yokuvimba amanzi enamathelayo eshisayo kanye netheyiphu yokuvimba amanzi, njll. esetshenziswa ngobuningi ekukhiqizweni kwentambo yokukhanya, Ithebula 2 ngezinye zezici zalezi zinto zokuvimba amanzi ukuze ziqhathaniswe.

4 Isiphetho

Ngamafuphi, intambo evimba amanzi iyinto enhle kakhulu evimba amanzi efanelekela ikhebula le-optical, inezici zokwakha okulula, ukusebenza okuthembekile, ukusebenza kahle kokukhiqiza okuphezulu, okulula ukuyisebenzisa; futhi ukusetshenziswa kwezinto ezigcwalisa ikhebula le-optical kunezinzuzo zesisindo esilula, ukusebenza okuthembekile kanye nezindleko eziphansi.

Isikhathi sokuthunyelwe: Julayi-16-2022