Isifinyezo: Isimiso sokuxhumanisa, ukuhlukaniswa, ukwakheka, inqubo kanye nemishini yezinto zokuvikela i-polyethylene ezixhunywe nge-silane zentambo nekhebula zichazwe kafushane, kanti ezinye izici zezinto zokuvikela i-polyethylene ezixhunywe nge-silane ngokwemvelo ekusetshenzisweni nasekusetshenzisweni kanye nezici ezithinta isimo sokuxhumanisa kwezinto ziyavezwa.

Amagama angukhiye: Ukuxhumanisa nge-silane; Ukuxhumanisa nge-cross-linking yemvelo; I-Polyethylene; Ukuvala; Ucingo nekhebula

Izinto zekhebula le-polyethylene elixhunywe nge-silane manje sezisetshenziswa kabanzi embonini yezintambo nezintambo njengento yokuvikela izintambo zikagesi ezine-voltage ephansi. Izinto ezisetshenziswa ekukhiqizeni ucingo nekhebula elixhunywe nge-cross-link, kanye ne-peroxide cross-linking kanye ne-irradiation cross-linking uma kuqhathaniswa nemishini yokukhiqiza edingekayo zilula, kulula ukuzisebenzisa, ziphansi izindleko eziphelele kanye nezinye izinzuzo, sezibe yinto ehamba phambili yekhebula elixhunywe nge-cross-linked eline-voltage ephansi eline-insulation.

1. Isimiso sokuxhumanisa izinto zekhebula ezixhunywe nge-cross-linked Silane

Kunezinqubo ezimbili eziyinhloko ezihilelekile ekwenzeni i-silane cross-linked polyethylene: ukuhlanganisa kanye nokuhlanganisa. Enqubweni yokuhlanganisa, i-polymer ilahlekelwa yi-H-atom yayo ku-athomu yekhabhoni yesithathu ngaphansi kwesenzo se-initiator yamahhala kanye ne-pyrolysis ibe ama-free radicals, asabela neqembu le- – CH = CH2 le-vinyl silane ukukhiqiza i-polymer ehlanganisiwe equkethe iqembu le-trioxysilyl ester. Enqubweni yokuhlanganisa, i-graft polymer iqale i-hydrolyzed lapho kukhona amanzi ukukhiqiza i-silanol, kanti i- – OH ihlangana neqembu le-Si-OH eliseduze ukuze kwakheke isibopho se-Si-O-Si, ngaleyo ndlela ixhumanise ama-macromolecule e-polymer.

2. Izinto zekhebula ezixhunywe nge-Silane kanye nendlela yazo yokukhiqiza ikhebula

Njengoba wazi, kunezindlela zokukhiqiza zezinyathelo ezimbili nezinyathelo eyodwa zezintambo ezixhunywe nge-silane kanye nezintambo zazo. Umehluko phakathi kwendlela yezinyathelo ezimbili kanye nendlela yesinyathelo esisodwa ulele lapho inqubo yokufakelwa kwe-silane yenziwa khona, inqubo yokufakelwa kumkhiqizi wezinto zekhebula zendlela yezinyathelo ezimbili, inqubo yokufakelwa esitshalweni sokukhiqiza izintambo zendlela yesinyathelo esisodwa. Izinto zokufakelwa ze-polyethylene ezixhunywe nge-silane ezinezinyathelo ezimbili ezinesabelo esikhulu semakethe zakhiwe ngezinto ezibizwa ngokuthi yi-A kanye ne-B, kanti izinto ze-A ziyi-polyethylene exhunywe ngezinto ze-silane kanye ne-B ziyi-catalyst master batch. I-insulating core ibe isixhunywa emanzini afudumele noma umusi.

Kukhona olunye uhlobo lwe-silane cross-linked polyethylene insulator enezinyathelo ezimbili, lapho i-A material ikhiqizwa ngendlela ehlukile, ngokungenisa i-vinyl silane ngqo kwi-polyethylene ngesikhathi sokwenziwa ukuze kutholakale i-polyethylene enezintambo ze-silane.

Indlela yesinyathelo esisodwa nayo inezinhlobo ezimbili, inqubo yendabuko yesinyathelo esisodwa iwuhlobo lwezinto zokusetshenziswa ezahlukahlukene ngokwefomula ngesilinganiso sesistimu yokulinganisa ekhethekile, ibe yi-extruder ekhethekile eyenzelwe ngokukhethekile ngesinyathelo esisodwa ukuze kuqedwe ukuxhunyelelwa kanye nokukhishwa kwe-core insulation core, kule nqubo, akukho granulation, asikho isidingo sokubamba iqhaza kwesitshalo sezinto zekhebula, yifektri yekhebula ukuze kuqedwe yodwa. Le mishini yokukhiqiza ikhebula exhunywe nge-silane enesinyathelo esisodwa kanye nobuchwepheshe bokwenza izinto ingeniswa kakhulu kwamanye amazwe futhi iyabiza.

Olunye uhlobo lwezinto zokufakelwa i-polyethylene ezixhunywe nge-silane ezinezinyathelo ezi-1 lukhiqizwa abakhiqizi bezinto zekhebula, zonke ziyizinto zokusetshenziswa ngokwefomula ngesilinganiso sendlela ekhethekile yokuxuba ndawonye, epakishwe futhi ithengiswe, azikho izinto ze-A kanye nezinto ze-B, isitshalo sekhebula singaba ngqo ku-extruder ukuze siqedele isinyathelo ngesikhathi esifanayo ukufakelwa kanye nokukhishwa kwe-core yokufakelwa ikhebula. Isici esiyingqayizivele sale ndlela ukuthi asikho isidingo sezinto zokufakelwa ezikhethekile ezibizayo, njengoba inqubo yokufakelwa i-silane ingaqedwa ku-extruder ejwayelekile ye-PVC, futhi indlela yezinyathelo ezimbili iqeda isidingo sokuxuba izinto ze-A kanye ne-B ngaphambi kokukhishwa.

3. Ukwakheka kokwakheka

Ukwakheka kwezinto zekhebula le-silane cross-linked polyethylene ngokuvamile kwakhiwa yi-resin, i-initiator, i-silane, i-antioxidant, i-polymerization inhibitor, i-catalyst, njll.

(1) I-base resin ngokuvamile iyi-low density polyethylene (LDPE) resin ene-melt index (MI) engu-2, kodwa muva nje, ngokuthuthukiswa kobuchwepheshe be-synthetic resin kanye nokucindezela kwezindleko, i-linear low density polyethylene (LLDPE) nayo isetshenziswe noma isetshenziswe kancane njenge-base resin yale nto. Ama-resin ahlukene avame ukuba nomthelela omkhulu ekuhlanganisweni nasekuxhumeni ngenxa yokwehluka kwesakhiwo sawo sangaphakathi se-macromolecule, ngakho-ke ukwakheka kuzoshintshwa ngokusebenzisa ama-base resin ahlukene noma uhlobo olufanayo lwe-resin oluvela kubakhiqizi abahlukene.

(2) Isiqalisi esivame ukusetshenziswa yi-diisopropyl peroxide (DCP), isihluthulelo ukuqonda inani lenkinga, okuncane kakhulu ukubangela ukuxhunyelelwa kwe-silane akwanele; okuningi kakhulu ukubangela ukuxhumanisa kwe-polyethylene, okunciphisa ukugeleza kwayo, ubuso be-extruded insulation core buqinile, kunzima ukukucindezela uhlelo. Njengoba inani lesiqalisi elingeziwe lincane kakhulu futhi libucayi, kubalulekile ukulihlakaza ngokulinganayo, ngakho-ke ngokuvamile lifakwa kanye ne-silane.

(3) I-Silane ivame ukusetshenziswa i-silane engagcwalisiwe ye-vinyl, kufaka phakathi i-vinyl trimethoxysilane (A2171) kanye ne-vinyl triethoxysilane (A2151), ngenxa yesilinganiso se-hydrolysis esisheshayo se-A2171, ngakho khetha abantu abaningi be-A2171. Ngokufanayo, kunenkinga yokwengeza i-silane, abakhiqizi bezinto zekhebula zamanje bazama ukufeza umkhawulo wayo ophansi ukuze banciphise izindleko, ngoba i-silane ingeniswa, intengo ibiza kakhulu.

(4) I-anti-oxidant iwukuqinisekisa ukuzinza kokucubungula i-polyethylene kanye nekhebula elilwa nokuguga kanye nokungezwa, i-anti-oxidant enqubweni yokufakelwa kwe-silane inendima yokuvimbela ukusabela kokufakelwa, ngakho-ke inqubo yokufakelwa, ukungezwa kwe-anti-oxidant kufanele kuqashelwe, inani elingeziwe licabangele inani le-DCP ukuze lifane nokukhethwa. Enqubweni yokuhlanganisa izigaba ezimbili, iningi le-antioxidant lingangezwa ku-catalyst master batch, okunganciphisa umthelela enqubweni yokuhlanganisa. Enqubweni yokuhlanganisa izigaba eyodwa, i-antioxidant ikhona kuyo yonke inqubo yokuhlanganisa, ngakho-ke ukukhetha izinhlobo nenani kubaluleke kakhulu. Ama-antioxidants asetshenziswa njalo yi-1010, 168, 330, njll.

(5) I-polymerization inhibitor yengezwa ukuze kuvinjelwe ukuxhunyelelwa kanye nenqubo yokuxhumanisa ye-cross-linking yemiphumela emibi eyenzekayo, enkambisweni yokuxhunyelelwa ukuze kufakwe i-ejenti yokulwa nokuxhumanisa, kunganciphisa ngempumelelo ukuvela kwe-C2C cross-linking, ngaleyo ndlela kuthuthukiswe uketshezi lokucubungula, ngaphezu kwalokho, ukungezwa kwe-graft ezimweni ezifanayo kuzokwandulelwa yi-hydrolysis ye-silane ku-polymerization inhibitor kunganciphisa i-hydrolysis ye-polyethylene exhunyelelwe, ukuthuthukisa ukuzinza kwesikhathi eside kwezinto ezixhunyelelwe.

(6) Ama-Catalyst avame ukuba yi-organotin derivatives (ngaphandle kokuxhumanisa kwemvelo), okuvame kakhulu yi-dibutyltin dilaurate (DBDTL), evame ukungezwa ngesimo se-masterbatch. Enqubweni yezinyathelo ezimbili, i-graft (izinto ze-A) kanye ne-catalyst master batch (izinto ze-B) zipakishwa ngokwehlukana futhi izinto ze-A kanye ne-B zixutshwa ndawonye ngaphambi kokungezwa ku-extruder ukuvimbela ukuxhumanisa kwangaphambili kwezinto ze-A. Endabeni ye-single-step silane cross-linked polyethylene insulation, i-polyethylene esephaketheni ayikakapakishwa, ngakho-ke akukho nkinga yokuxhumanisa kwangaphambili ngakho-ke i-catalyst ayidingi ukuhlanganiswa ngokwehlukana.

Ngaphezu kwalokho, kunezinhlayiya ze-silane ezihlanganisiwe ezitholakala emakethe, eziyinhlanganisela ye-silane, i-initiator, i-antioxidant, ezinye izinto zokugcoba kanye nama-anti-copper agents, futhi ngokuvamile zisetshenziswa ezindleleni zokuxhumanisa ze-silane ezinesinyathelo esisodwa ezitshalweni zekhebula.

Ngakho-ke, ukwakheka kwe-silane cross-linked polyethylene insulation, okwakheka kwayo okungabhekwa njengokuyinkimbinkimbi kakhulu futhi kuyatholakala olwazini olufanele, kodwa ukwakheka kokukhiqiza okufanele, kuncike ekulungisweni okuthile ukuze kuqedwe, okudinga ukuqonda okugcwele indima yezingxenye ekwakhiweni kanye nomthetho womthelela wazo ekusebenzeni kanye nethonya lazo elihlangene.

Ezinhlotsheni eziningi zezinto zekhebula, izinto zekhebula ezixhunywe nge-silane (noma isinyathelo ezimbili noma isinyathelo esisodwa) zibhekwa njengokuphela kwezinhlobo zezinqubo zamakhemikhali ezenzeka ekukhishweni, ezinye izinhlobo ezifana nezinto zekhebula ze-polyvinyl chloride (PVC) kanye nezinto zekhebula ze-polyethylene (PE), inqubo yokuqothula i-extrusion iyinqubo yokuxuba ngokomzimba, noma ngabe izinto zekhebula ezixhunywe nge-cross-linking kanye ne-irradiation, kungakhathaliseki ukuthi zisenqubo yokuqothula i-extrusion, noma uhlelo lwe-extrusion Cable, akukho nqubo yamakhemikhali eyenzekayo, ngakho-ke, uma kuqhathaniswa, ukukhiqizwa kwezinto zekhebula ezixhunywe nge-silane kanye nokukhishwa kwe-insulation yekhebula, ukulawula inqubo kubaluleke kakhulu.

4. Inqubo yokukhiqiza ukufakelwa kwe-polyethylene enezinyathelo ezimbili exhunywe nge-silane

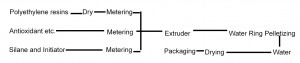

Inqubo yokukhiqizwa kwe-silane enezinyathelo ezimbili exhunywe nge-polyethylene insulation A ingamelwa kafushane yiSithombe 1.

Umfanekiso 1 Inqubo yokukhiqiza yezinto zokuvikela i-polyethylene ezine-silane ezinezinyathelo ezimbili A

Amanye amaphuzu abalulekile enkambisweni yokukhiqiza i-silane cross-linked polyethylene insulation enezinyathelo ezimbili:

(1) Ukomisa. Njengoba i-resin ye-polyethylene iqukethe inani elincane lamanzi, uma ikhishwa emazingeni okushisa aphezulu, amanzi asabela ngokushesha namaqembu e-silyl ukuze akhiqize ukuxhumanisa, okunciphisa ukugeleza kokuncibilika futhi kukhiqize ukuxhumanisa kwangaphambili. Izinto eziqediwe nazo ziqukethe amanzi ngemva kokupholisa amanzi, okungase futhi kubangele ukuxhumanisa kwangaphambili uma kungasuswa, futhi kumele komiswe. Ukuze kuqinisekiswe ikhwalithi yokomisa, kusetshenziswa iyunithi yokomisa ejulile.

(2) Ukulinganisa. Njengoba ukunemba kokwakheka kwezinto kubalulekile, isikali sokulinganisa esingenisiwe esingeniswayo ngokuvamile sisetshenziswa. I-resin ye-polyethylene kanye ne-antioxidant kulinganiswa futhi kondliwa nge-feed port ye-extruder, kuyilapho i-silane kanye ne-initiator kufakwa ngepompo yezinto eziwuketshezi emgqonyeni wesibili noma wesithathu we-extruder.

(3) Ukufakelwa kwe-Extrusion. Inqubo yokufakelwa kwe-silane iqedwa ku-extruder. Izilungiselelo zenqubo ye-extruder, okuhlanganisa izinga lokushisa, inhlanganisela yezikulufo, isivinini sesikulufo kanye nesivinini sokudla, kumele zilandele isimiso sokuthi izinto ezisesigabeni sokuqala se-extruder zingancibilikiswa ngokuphelele futhi zixutshwe ngokulinganayo, lapho ukubola kwangaphambi kwesikhathi kwe-peroxide kungafunwa, nokuthi izinto ezifanayo ngokuphelele esigabeni sesibili se-extruder kumele zibole ngokuphelele futhi inqubo yokufakelwa iqedwe. Amazinga okushisa ajwayelekile esigaba se-extruder (LDPE) aboniswe kuThebula 1.

Ithebula 1 Izinga lokushisa lezindawo zokukhipha ezinezinyathelo ezimbili

| Indawo yokusebenza | Indawo 1 | Indawo 2 | Indawo 3 ① | Indawo 4 | Indawo 5 |

| Izinga lokushisa P °C | 140 | 145 | 120 | 160 | 170 |

| Indawo yokusebenza | Indawo 6 | Indawo 7 | Indawo 8 | Indawo 9 | Umlomo ufa |

| Izinga lokushisa °C | 180 | 190 | 195 | 205 | 195 |

① yilapho kufakwe khona i-silane.

Ijubane lesikulufu se-extruder linquma isikhathi sokuhlala kanye nomphumela wokuxubana kwezinto eziku-extruder, uma isikhathi sokuhlala sifushane, ukubola kwe-peroxide akuphelele; uma isikhathi sokuhlala side kakhulu, i-viscosity yezinto ezikhishwe iyanda. Ngokuvamile, isikhathi sokuhlala esimaphakathi se-granule ku-extruder kufanele silawulwe ekuqhekekeni kwengxenye yokuphila kwengxenye yesikhathi se-initiator izikhathi ezi-5-10. Ijubane lokuphakela aligcini nje ngokuba nomthelela othile esikhathini sokuhlala kwezinto, kodwa futhi nasekuxubeni nasekugundeni kwezinto, ukukhetha isivinini sokudla esifanele nakho kubaluleke kakhulu.

(4) Ukupakishwa. Izinto zokuvikela ezixhunywe nge-silane ezinezinyathelo ezimbili kufanele zipakishwe ezikhwameni ze-aluminium-plastic ezihlanganisiwe emoyeni oqondile ukuze kuqedwe umswakama.

5. Inqubo yokukhiqiza izinto zokuvikela i-polyethylene exhunywe nge-silane enesinyathelo esisodwa

Izinto zokufakelwa ze-polyethylene ezixhunywe nge-silane ezinesinyathelo esisodwa ngenxa yenqubo yazo yokufakelwa zisekukhishweni kwefektri yekhebula kwe-core yokufakelwa kwekhebula, ngakho-ke izinga lokushisa lokufakelwa kwekhebula liphakeme kakhulu kunendlela yesinyathelo ezimbili. Nakuba ifomula yokufakelwa kwe-polyethylene exhunywe nge-silane enesinyathelo esisodwa icatshangelwe ngokugcwele ekusakazweni okusheshayo kwe-initiator kanye ne-silane kanye ne-material shear, kodwa inqubo yokufakelwa kumele iqinisekiswe yizinga lokushisa, okuyisitshalo sokukhiqiza i-polyethylene exhunywe nge-silane esinesinyathelo esisodwa esigcizelele ngokuphindaphindiwe ukubaluleka kokukhetha okulungile kwezinga lokushisa lokufakelwa, izinga lokushisa lokufakelwa elijwayelekile elinconywayo liboniswe kuThebula 2.

Ithebula 2 Izinga lokushisa le-extruder lesinyathelo esisodwa lendawo ngayinye (iyunithi: ℃)

| Indawo | Indawo 1 | Indawo 2 | Indawo 3 | Indawo 4 | I-Flange | Ikhanda |

| Izinga lokushisa | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Lokhu kungenye yobuthakathaka benqubo ye-polyethylene exhunywe nge-silane enesinyathelo esisodwa, ngokuvamile engadingeki lapho kukhishwa izintambo ngezinyathelo ezimbili.

6. Imishini yokukhiqiza

Imishini yokukhiqiza iyisiqinisekiso esibalulekile sokulawulwa kwenqubo. Ukukhiqizwa kwezintambo ezixhunywe nge-silane kudinga izinga eliphezulu kakhulu lokunemba kokulawulwa kwenqubo, ngakho-ke ukukhetha imishini yokukhiqiza kubaluleke kakhulu.

Ukukhiqizwa kwezinto zokufakelwa ze-polyethylene ezihlanganisiwe nge-silane ezinezinyathelo ezimbili. Imishini yokukhiqiza izinto, okwamanje i-extruder ye-isotropic parallel twin-screw extruder yasekhaya enesisindo esingenasisindo esingenisiwe, amadivayisi anjalo angahlangabezana nezidingo zokunemba kokulawula inqubo, ukukhetha ubude nobubanzi be-extruder ye-twin-screw ukuqinisekisa ukuthi isikhathi sokuhlala kwezinto, ukukhetha kwesisindo esingenasisindo esingenisiwe ukuqinisekisa ukunemba kwezithako. Yiqiniso kunemininingwane eminingi yemishini okudingeka inikezwe ukunakwa okugcwele.

Njengoba kushiwo ngaphambili, imishini yokukhiqiza ikhebula le-silane elixhunywe ngesinyathelo esisodwa esitshalweni sekhebula ingeniswa kwamanye amazwe, iyabiza, abakhiqizi bemishini yasekhaya abanayo imishini yokukhiqiza efanayo, isizathu ukuntuleka kokubambisana phakathi kwabakhiqizi bemishini nabacwaningi befomula nezinqubo.

7. Izinto zokuvikela i-polyethylene ezixhumene ngokwemvelo ze-Silane

Izinto zokuvikela i-polyethylene ezixhumene ngokwemvelo ze-silane ezakhiwe eminyakeni yamuva nje zingaxhunyaniswa ngaphansi kwezimo zemvelo zingakapheli izinsuku ezimbalwa, ngaphandle kokucwiliswa ngomusi noma emanzini afudumele. Uma kuqhathaniswa nendlela yendabuko yokuxhumanisa i-silane, le nto inganciphisa inqubo yokukhiqiza yabakhiqizi bekhebula, inciphise kakhulu izindleko zokukhiqiza futhi ikhulise ukusebenza kahle kokukhiqiza. Ukufakwa kwe-polyethylene okuxhumene ngokwemvelo kwe-silane kuqashelwa futhi kusetshenziswa abakhiqizi bekhebula.

Eminyakeni yamuva nje, ukufakelwa kwe-polyethylene okuhlanganiswe ne-silane yemvelo yasekhaya kuye kwavuthwa futhi kwakhiqizwa ngobuningi obukhulu, ngezinzuzo ezithile ngentengo uma kuqhathaniswa nezinto ezingeniswa kwamanye amazwe.

7. 1 Imibono yokwenza izinto zokuvikela i-silane ezixhumene ngokwemvelo nge-polyethylene

Ukufakwa kwe-polyethylene okuxhumene ne-silane yemvelo kukhiqizwa ngenqubo yezinyathelo ezimbili, kanye nokwakheka okufanayo okuhlanganisa i-base resin, i-initiator, i-silane, i-antioxidant, i-polymerisation inhibitor kanye ne-catalyst. Ukwakheka kwe-silane natural cross-linked polyethylene insulators kusekelwe ekwandiseni izinga lokufakwa kwe-silane lezinto ze-A kanye nokukhetha i-catalyst esebenza kahle kakhulu kune-silane water water cross-linked polyethylene insulators. Ukusetshenziswa kwezinto ze-A ezinezinga eliphezulu lokufakwa kwe-silane kuhlanganiswe ne-catalyst esebenza kahle kuzokwenza i-silane cross-linked polyethylene insulator ikwazi ukuxhuma ngokushesha ngisho noma amazinga okushisa aphansi futhi inomswakama owanele.

Izinto ze-A ze-silane ezingenisiwe ezixhumene ngokwemvelo ne-polyethylene zihlanganiswa yi-copolymerisation, lapho okuqukethwe kwe-silane kungalawulwa khona ezingeni eliphezulu, kanti ukukhiqizwa kwezinto ze-A ezinezinga eliphezulu lokuxhunyelelwa ngokuxhunyelelwa kwe-silane kunzima. I-resin eyisisekelo, i-initiator kanye ne-silane esetshenziswa ku-recipe kufanele kushintshwe futhi kulungiswe ngokwezinhlobonhlobo kanye nokwengezwa.

Ukukhethwa kwe-resist kanye nokulungiswa komthamo wayo nakho kubalulekile, njengoba ukwanda kwesilinganiso sokuxhunyelelwa kwe-silane kuholela ekuphenduleni okwengeziwe kwe-CC crosslinking side. Ukuze kuthuthukiswe ukugeleza kokucubungula kanye nesimo sobuso bento ye-A yokukhipha ikhebula okulandelayo, inani elifanele le-polymerization inhibitor liyadingeka ukuze kuvinjelwe ngempumelelo i-CC crosslinking kanye ne-pre-crosslinking.

Ngaphezu kwalokho, ama-catalyst adlala indima ebalulekile ekwandiseni izinga lokuxhumanisa futhi kufanele akhethwe njengama-catalyst asebenzayo aqukethe izakhi ezingenayo insimbi yokuguquka.

7. 2 Isikhathi sokuxhumanisa se-silane ngokwemvelo esixhumene ne-polyethylene insulation

Isikhathi esidingekayo ukuze kuqedwe ukuhlanganiswa kwe-silane natural cross-linked polyethylene insulation esimweni sayo semvelo sincike ekushiseni, umswakama kanye nobukhulu besendlalelo sokufakelwa. Uma izinga lokushisa kanye nomswakama liphakeme, ukujiya kwesendlalelo sokufakelwa kuba kuncane, isikhathi sokufakelwa sifushane, futhi isikhathi eside siphambene nalokho. Njengoba izinga lokushisa kanye nomswakama kuhluka kuye ngesifunda kanye nesizini, ngisho nasendaweni efanayo nangesikhathi esifanayo, izinga lokushisa kanye nomswakama namuhla nakusasa kuzohluka. Ngakho-ke, ngesikhathi sokusetshenziswa kwezinto, umsebenzisi kufanele anqume isikhathi sokufakelwa ngokuya ngezinga lokushisa kanye nomswakama wendawo kanye nendawo, kanye nokucaciswa kwekhebula kanye nobukhulu besendlalelo sokufakelwa.

Isikhathi sokuthunyelwe: Agasti-13-2022