Izinto Zekhebula Zokuvimba Amanzi

Izinto zokuvimba amanzi ngokuvamile zingahlukaniswa ngezigaba ezimbili: ukuvimba amanzi okusebenzayo kanye nokuvimba amanzi okungenzi lutho. Ukuvimba amanzi okusebenzayo kusebenzisa izakhiwo zokumunca amanzi nokuvuvukala kwezinto ezisebenzayo. Lapho igobolondo noma ijoyinti lonakele, lezi zinto ziyanda lapho zithintana namanzi, zinciphise ukungena kwawo ngaphakathi kwekhebula. Izinto ezinjalo zifaka phakathiijeli enwebekayo emunca amanzi, iteyipu yokuvimba amanzi, impuphu yokuvimba amanzi,intambo yokuvimba amanzi, kanye nentambo yokuvimba amanzi. Ngakolunye uhlangothi, ukuvimba amanzi okungenamsebenzi kusebenzisa izinto ezivikela amanzi ukuze kuvinjwe amanzi ngaphandle kwekhebula lapho igobolondo lonakele. Izibonelo zezinto zokuvimba amanzi okungenamsebenzi yi-paste egcwele uphethiloli, i-hot melt glue, kanye ne-paste ekhulisa ukushisa.

I. Izinto Zokuvimba Amanzi Ezingasebenzi

Ukugcwaliswa kwezinto zokuvimba amanzi ezingasebenzi, njenge-petroleum paste, ezintanjeni kwakuyindlela eyinhloko yokuvimba amanzi ezintanjeni zamandla zokuqala. Le ndlela ivimbela amanzi ukuthi angangeni entanjeni kodwa inezinkinga ezilandelayo:

1.Iyandisa kakhulu isisindo sekhebula;

2. Kubangela ukwehla kokusebenza kwekhebula eliqhubayo;

3. I-petroleum paste ingcolisa kakhulu ama-cable joints, okwenza ukuhlanza kube nzima;

4. Inqubo ephelele yokugcwalisa kunzima ukuyilawula, futhi ukugcwalisa okungaphelele kungabangela ukusebenza okungekuhle kokuvimba amanzi.

II. Izinto Zokuvimba Amanzi Ezisebenzayo

Njengamanje, izinto zokuvimba amanzi ezisebenzayo ezisetshenziswa ezintanjeni ikakhulukazi iteyipu yokuvimba amanzi, impuphu yokuvimba amanzi, intambo yokuvimba amanzi, kanye nentambo yokuvimba amanzi. Uma kuqhathaniswa ne-petroleum paste, izinto zokuvimba amanzi ezisebenzayo zinezici ezilandelayo: ukumuncwa kwamanzi okuphezulu kanye nesivinini sokuvuvukala okuphezulu. Zingamunca amanzi ngokushesha futhi zivuvuke ngokushesha ukuze zakhe into efana nejeli evimba ukungena kwamanzi, ngaleyo ndlela ziqinisekise ukuphepha kokufakwa kwentambo. Ngaphezu kwalokho, izinto zokuvimba amanzi ezisebenzayo zilula, zihlanzekile, futhi kulula ukuzifaka nokuzihlanganisa. Kodwa-ke, zinezinkinga ezithile:

1. Impuphu evimba amanzi kunzima ukuyinamathisela ngokulinganayo;

2. Itheyiphu noma uboya obuvimba amanzi bungandisa ububanzi bangaphandle, buphazamise ukushabalaliswa kokushisa, busheshise ukuguga kokushisa kwekhebula, futhi bunciphise amandla okudlulisa ikhebula;

3. Izinto ezisebenzayo zokuvimba amanzi ngokuvamile zibiza kakhulu.

Ukuhlaziywa Kokuvimba Amanzi: Njengamanje, indlela eyinhloko eShayina yokuvimbela amanzi ukuthi angangeni engqimbeni yokuvimbela izintambo ukwandisa ungqimba olungangeni manzi. Kodwa-ke, ukuze sifinyelele ukuvimba kwamanzi okuphelele ezintanjeni, akumelwe sicabangele nje kuphela ukungena kwamanzi ngemisebe kodwa futhi sivimbele ngempumelelo ukusabalala kwamanzi isikhathi eside uma engena entanjeni.

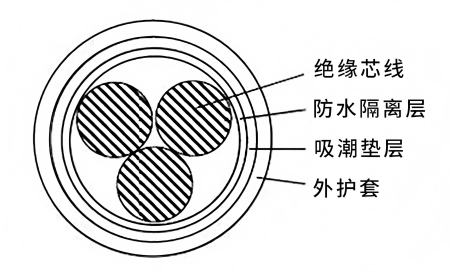

Isendlalelo Sokuhlukaniswa Okungangeni Manzi se-Polyethylene (Inner Sheath): Ukukhipha isendlalelo sokuvimbela amanzi se-polyethylene, kuhlanganiswe nesendlalelo somcamelo esimunca umswakama (njengetheyiphu yokuvimbela amanzi), kungahlangabezana nezidingo zokuvimbela amanzi okude kanye nokuvikelwa komswakama ezintanjeni ezifakwe ezindaweni ezinomswakama olinganiselayo. Isendlalelo sokuvimbela amanzi se-polyethylene kulula ukusenza futhi asidingi imishini eyengeziwe.

Itheyiphu ye-Aluminium Embozwe ngepulasitiki Isendlalelo Sokuhlukaniswa Kwamanzi Esihlanganisiwe se-Polyethylene: Uma izintambo zifakwe emanzini noma ezindaweni ezimanzi kakhulu, amandla okuvimba amanzi e-radial ezingqimbeni zokuhlukanisa ze-polyethylene angase anganele. Ngezintambo ezidinga ukusebenza okuphezulu kokuvimba amanzi e-radial, manje sekuvamile ukugoqa ungqimba lwetheyiphu ehlanganisiwe ye-aluminium-plastic nxazonke kwengqikithi yekhebula. Lesi sivalo simelana namanzi izikhathi ezingamakhulu noma ngisho nezinkulungwane kune-polyethylene emsulwa. Uma nje umthungo wetheyiphu ehlanganisiwe uboshwe futhi uvalwe ngokuphelele, ukungena kwamanzi cishe akunakwenzeka. Itheyiphu ehlanganisiwe ye-aluminium-plastic idinga inqubo yokugoqa nokubopha ende, ehilela ukutshalwa kwezimali okwengeziwe kanye nokuguqulwa kwemishini.

Ekwenzeni kobunjiniyela, ukufeza ukuvimba kwamanzi okude kuyinkimbinkimbi kakhulu kunokuvimba kwamanzi okuqondile. Izindlela ezahlukahlukene, njengokushintsha isakhiwo somqhubi sibe umklamo ocindezelwe ngokuqinile, zisetshenzisiwe, kodwa imiphumela ibe mincane ngoba kusenezikhala kumqhubi ocindezelwe ezivumela amanzi ukuthi asakazeke ngesenzo se-capillary. Ukuze kufezwe ukuvimba kwamanzi okude kwangempela, kubalulekile ukugcwalisa izikhala kumqhubi ovalelekile ngezinto zokuvimba amanzi. Amazinga amabili alandelayo ezilinganiso nezakhiwo angasetshenziswa ukufeza ukuvimba kwamanzi okude ezintanjeni:

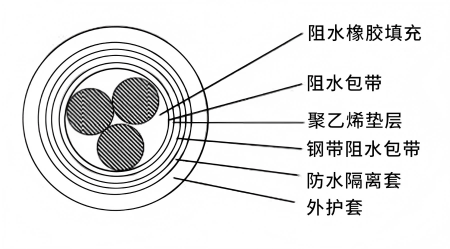

1. Ukusebenzisa ama-conductor avimba amanzi. Faka intambo evimba amanzi, impuphu evimba amanzi, intambo evimba amanzi, noma ugoqe iteyipu evimba amanzi uzungeze i-conductor ecindezelwe ngokuqinile.

2.Ukusetshenziswa kwama-core avimba amanzi. Ngesikhathi senqubo yokukhiqiza ikhebula, gcwalisa i-core ngentambo evimba amanzi, intambo, noma ugoqe i-core ngetheyiphu evimbela amanzi ehambisa amanzi kancane noma evikela umswakama.

Njengamanje, inselele enkulu ekuvinjweni kwamanzi okude isezinjinini ezivimba amanzi—indlela yokugcwalisa izinto ezivimba amanzi phakathi kwezinjinini nokuthi yiziphi izinto ezivimba amanzi okufanele uzisebenzise isalokhu igxile ocwaningweni.

Ⅲ. Isiphetho

Ubuchwepheshe bokuvimba amanzi ngemisebe busebenzisa kakhulu izendlalelo zokuhlukanisa amanzi ezimbozwe ungqimba lokuvikela umqhubi, kanye nesendlalelo somcamelo esimunca umswakama ngaphandle. Kumakhebula ane-voltage ephakathi, i-aluminium-plastic composite tape ivame ukusetshenziswa, kuyilapho amakhebula ane-voltage ephezulu evame ukusebenzisa amajakethi okuvala insimbi enomthofu, i-aluminium, noma insimbi engagqwali.

Ubuchwepheshe bokuvimba amanzi esikhathi eside bugxile kakhulu ekugcwaliseni izikhala phakathi kwezintambo eziqhuba amanzi ngezinto zokuvimba amanzi ukuze kuvinjelwe ukusabalala kwamanzi enkabeni. Kusukela ekuthuthukisweni kobuchwepheshe bamanje, ukugcwalisa ngempuphu yokuvimba amanzi kusebenza kahle ekuvimbeleni amanzi esikhathi eside.

Ukufinyelela izintambo ezingangeni manzi kuzothinta ngokungenakugwenywa ukushabalaliswa kokushisa kwekhebula kanye nokusebenza kwalo okuhambisa umoya, ngakho-ke kubalulekile ukukhetha noma ukuklama isakhiwo sekhebula esivimba amanzi esifanele ngokusekelwe ezidingweni zobunjiniyela.

Isikhathi sokuthunyelwe: Feb-14-2025