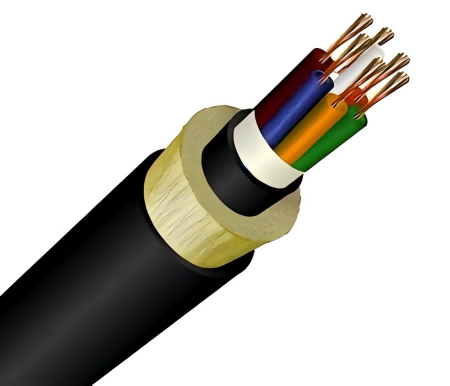

Ukuqinisekisa ukuthi i-core yekhebula le-optical ivikelwe ekulimaleni okuhlobene nomshini, ukushisa, amakhemikhali, kanye nomswakama, kumele ifakwe i-sheath noma ngisho nezendlalelo zangaphandle ezengeziwe. Lezi zinyathelo zandisa ngempumelelo impilo yesevisi yezintambo ze-optical.

Ama-sheath asetshenziswa kakhulu kuma-optical cable afaka phakathi ama-A-sheath (ama-sheath aboshwe nge-aluminium-polyethylene), ama-S-sheath (ama-sheath aboshwe ngensimbi-polyethylene), kanye nama-sheath e-polyethylene. Kuma-optical cable ajulile, ama-sheath avaliwe ngensimbi avame ukusetshenziswa.

Ama-sheath e-polyethylene enziwe ngomugqa ophansi, ophakathi, nomaizinto ze-polyethylene emnyama ezixinene kakhulu, ngokuvumelana nezindinganiso ze-GB/T15065. Ubuso beshelufu le-polyethylene emnyama kufanele bube bushelelezi futhi bufane, bungabi nama-bubbles abonakalayo, imigodi, noma imifantu. Uma isetshenziswa njengeshelufu langaphandle, ubukhulu obujwayelekile kufanele bube ngu-2.0 mm, kanye nobukhulu obuncane obungu-1.6 mm, kanye nobukhulu obujwayelekile kunoma iyiphi ingxenye enqamulayo akufanele bube ngaphansi kuka-1.8 mm. Izakhiwo zemishini nezomzimba zeshelufu kufanele zihlangabezane nezidingo ezichazwe ku-YD/T907-1997, Ithebula 4.

I-A-sheath yakhiwe ungqimba lokuvimbela umswakama olwenziwe ngokugoqwa okude nokugoqeneiteyipu ye-aluminium ehlanganiswe ngepulasitiki, kuhlanganiswe ne-sheath ye-polyethylene emnyama ekhishwe ngaphandle. I-sheath ye-polyethylene ibopha ne-tape ehlanganisiwe kanye nemiphetho ehambisanayo ye-tape, engaqiniswa ngokunamathela uma kudingeka. Ububanzi obuhambisanayo be-tape ehlanganisiwe akufanele bube ngaphansi kuka-6 mm, noma kuma-core ekhebula anobubanzi obungaphansi kuka-9.5 mm, akufanele bube ngaphansi kuka-20% womjikelezo we-core. Ubukhulu obujwayelekile be-sheath ye-polyethylene bungu-1.8 mm, nobukhulu obuncane obungu-1.5 mm, kanye nobukhulu obujwayelekile obungaphansi kuka-1.6 mm. Kwezendlalelo zangaphandle zohlobo 53, ubukhulu obujwayelekile bungu-1.0 mm, ubukhulu obuncane bungu-0.8 mm, kanye nobukhulu obujwayelekile bungu-0.9 mm. I-tape ehlanganisiwe ye-aluminium-plastic kufanele ihlangabezane ne-YD/T723.2 standard, ne-tape ye-aluminium enobukhulu obujwayelekile obungu-0.20 mm noma u-0.15 mm (ubuncane obungu-0.14 mm) kanye nobukhulu befilimu ehlanganisiwe obungu-0.05 mm.

Kuvunyelwe ukuhlanganisa amatheyipu ambalwa ahlanganisiwe ngesikhathi sokukhiqiza izintambo, uma nje isikhala sokuhlangana singengaphansi kwamamitha angu-350. Lawa matheyipu kumele aqinisekise ukuqhubeka kukagesi futhi abuyisele ungqimba lwepulasitiki oluhlanganisiwe. Amandla ethayipu akumele abe ngaphansi kwamaphesenti angu-80 amandla ethayipu yokuqala.

I-S-sheath isebenzisa ungqimba lokuvimbela umswakama olwenziwe ngothayela olugoqwe ngobude futhi oluhlanganisiweiteyipu yensimbi eboshwe ngepulasitiki, kuhlanganiswe ne-sheath ye-polyethylene emnyama ekhishwe ngaphandle. I-sheath ye-polyethylene ibopha ne-tape ehlanganisiwe kanye nemiphetho ehambisanayo ye-tape, engaqiniswa nge-glue uma kudingeka. I-tape ehlanganisiwe ehlanganisiwe kufanele yakhe isakhiwo esifana nendandatho ngemva kokusonga. Ububanzi bokugqagqana akufanele bube ngaphansi kuka-6 mm, noma kuma-core ekhebula anobubanzi obungaphansi kuka-9.5 mm, akufanele bube ngaphansi kuka-20% womjikelezo we-core. Ubukhulu obujwayelekile be-sheath ye-polyethylene bungu-1.8 mm, ubukhulu obuncane obungu-1.5 mm, kanye nobukhulu obujwayelekile obungaphansi kuka-1.6 mm. I-tape ehlanganisiwe yensimbi-ipulasitiki kufanele ihlangabezane ne-YD/T723.3 standard, ne-tape yensimbi enobukhulu obuncane obungu-0.15 mm (ubuncane obungu-0.13 mm) kanye nobukhulu befilimu ehlanganisiwe obungu-0.05 mm.

Ama-composite tape joints avunyelwe ngesikhathi sokukhiqiza izintambo, ngesikhala esincane samalunga esingamamitha angu-350. I-steel tape kufanele ihlanganiswe nezinqe, iqinisekise ukuqhubeka kukagesi futhi ibuyisele ungqimba oluhlanganisiwe. Amandla e-joint akumele abe ngaphansi kuka-80% wamandla e-composite tape yokuqala.

Itheyiphu ye-aluminium, i-steel tape, kanye nezendlalelo zensimbi ezisetshenziselwa izithiyo zomswakama kumele zigcine ukuqhubeka kukagesi ngobude bekhebula. Kuma-sheath ahlanganisiwe (kufaka phakathi izendlalelo zangaphandle zohlobo 53), amandla okuxebuka phakathi kwe-aluminium noma i-steel tape kanye ne-polyethylene sheath, kanye namandla okuxebuka phakathi kwemiphetho egqagqene ye-aluminium noma i-steel tape, akufanele kube ngaphansi kuka-1.4 N/mm. Kodwa-ke, lapho kufakwa into noma i-coating evimba amanzi ngaphansi kwe-aluminium noma i-steel tape, amandla okuxebuka emaphethelweni agqagqene awadingeki.

Lesi sakhiwo sokuvikela esibanzi siqinisekisa ukuqina nokuthembeka kwezintambo ezibonakalayo ezindaweni ezahlukene, okuhlangabezana ngempumelelo nezidingo zezinhlelo zokuxhumana zesimanje.

Isikhathi sokuthunyelwe: Jan-20-2025