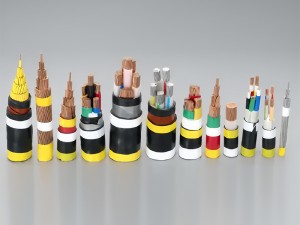

Isakhiwo sekhebula sibonakala silula, empeleni, ingxenye ngayinye yaso inenjongo yayo ebalulekile, ngakho-ke izinto zengxenye ngayinye kumele zikhethwe ngokucophelela lapho kukhiqizwa ikhebula, ukuze kuqinisekiswe ukuthembeka kwekhebula elenziwe ngalezi zinto ngesikhathi sokusebenza.

1. Izinto zomqhubi

Ngokomlando, izinto ezazisetshenziswa kuma-cable conductors kwakuyithusi ne-aluminium. I-Sodium nayo yazanywa isikhashana. Ithusi ne-aluminium zinokudluliswa kukagesi okungcono, futhi inani lethusi lincane uma lidlulisa ugesi ofanayo, ngakho ububanzi bangaphandle bomqhubi wethusi buncane kunobomqhubi we-aluminium. Intengo ye-aluminium iphansi kakhulu kunethusi. Ngaphezu kwalokho, ngoba ubuningi bethusi bukhulu kunobe-aluminium, noma ngabe umthamo wokuthwala ugesi uyafana, ingxenye evundlile yomqhubi we-aluminium inkulu kunomqhubi wethusi, kodwa ikhebula lomqhubi we-aluminium lisalula kunekhebula lomqhubi wethusi.

2. Izinto zokuvala umoya

Kunezinto eziningi zokuvikela umswakama ezingasetshenziswa yizintambo zikagesi ze-MV, ngisho nezinto zokuvikela umswakama ezivuthwe ngobuchwepheshe, ezisetshenziswe ngempumelelo iminyaka engaphezu kwe-100. Namuhla, ukuvikela umswakama kwe-polymer okukhishwe kuye kwamukelwa kabanzi. Izinto zokuvikela umswakama kwe-polymer okukhishwe zifaka i-PE(LDPE kanye ne-HDPE), i-XLPE, i-WTR-XLPE kanye ne-EPR. Lezi zinto ziyi-thermoplastic kanye ne-thermosetting. Izinto ze-thermoplastic ziyashintshashintsha uma zishiswa, kuyilapho izinto ze-thermoset zigcina isimo sazo emazingeni okushisa okusebenza.

2.1. Ukuvikela amaphepha

Ekuqaleni kokusebenza kwazo, izintambo ezifakwe ephepheni zithwala umthwalo omncane kuphela futhi zigcinwa kahle. Kodwa-ke, abasebenzisi bamandla bayaqhubeka nokwenza izintambo ezithwala umthwalo omkhulu kakhulu, izimo zokuqala zokusebenzisa azisafaneleki izidingo zekhebula lamanje, khona-ke ulwazi oluhle lokuqala alukwazi ukumela ukusebenza kwesikhathi esizayo kwekhebula kumele kube kuhle. Eminyakeni yamuva nje, izintambo ezifakwe ephepheni azisetshenziswa kakhulu.

2.2.I-PVC

I-PVC isasetshenziswa njengento yokuvikela izintambo ze-1kV ezinama-voltage aphansi futhi iyinto yokuvikela izintambo. Kodwa-ke, ukusetshenziswa kwe-PVC ekuvimbeleni izintambo kuthathwa indawo ngokushesha yi-XLPE, kanti ukusetshenziswa kwe-sheath kuthathwa indawo ngokushesha yi-linear low density polyethylene (LLDPE), i-medium density polyethylene (MDPE) noma i-high density polyethylene (HDPE), kanti izintambo ezingezona eze-PVC zinezindleko eziphansi zomjikelezo wokuphila.

2.3. I-Polyethylene (PE)

I-polyethylene ephansi (LDPE) yasungulwa ngawo-1930 futhi manje isetshenziswa njenge-resin eyisisekelo yezinto ze-polyethylene exhumene (XLPE) kanye ne-polyethylene exhumene nezihlahla engangeni manzi (WTR-XLPE). Esimweni se-thermoplastic, izinga lokushisa eliphezulu lokusebenza le-polyethylene lingu-75 ° C, elingaphansi kwezinga lokushisa lokusebenza kwezintambo ezifakwe ephepheni (80~90 ° C). Le nkinga ixazululiwe ngokufika kwe-polyethylene exhunywe (XLPE), engahlangabezana noma idlule izinga lokushisa lokusebenza kwezintambo ezifakwe ephepheni.

2.4.I-polyethylene exhumene ne-cross-linked (XLPE)

I-XLPE iyinto yokulungisa ukushisa eyenziwe ngokuxuba i-polyethylene ephansi (i-LDPE) ne-ejenti yokuxhumanisa (njenge-peroxide).

Izinga lokushisa eliphezulu lokusebenza komqhubi wekhebula elifakwe i-XLPE lingu-90 ° C, isivivinyo sokulayisha ngokweqile sifinyelela ku-140 ° C, kanti izinga lokushisa le-short-circuit lingafinyelela ku-250 ° C. I-XLPE inezici ezinhle kakhulu ze-dielectric futhi ingasetshenziswa kububanzi bamandla kagesi obusukela ku-600V kuya ku-500kV.

2.5. Isihlahla esingangeni manzi I-polyethylene exhumene ne-Cross-linked (WTR-XLPE)

Isenzakalo sesihlahla samanzi sizonciphisa impilo yekhebula le-XLPE. Kunezindlela eziningi zokunciphisa ukukhula kwesihlahla samanzi, kodwa enye yezindlela ezamukelekayo kakhulu ukusebenzisa izinto zokuvikela ezenziwe ngobunjiniyela obukhethekile ezenzelwe ukuvimbela ukukhula kwesihlahla samanzi, ezibizwa ngokuthi i-polyethylene WTR-XLPE yesihlahla esingangeni manzi.

2.6. Irabha ye-ethylene propylene (EPR)

I-EPR iyinto yokulungisa ukushisa eyenziwe nge-ethylene, i-propylene (ngezinye izikhathi i-monomer yesithathu), kanti i-copolymer yama-monomer amathathu ibizwa ngokuthi i-ethylene propylene diene rubber (EPDM). Kumazinga okushisa abanzi, i-EPR ihlala ithambile futhi inokumelana okuhle kwe-corona. Kodwa-ke, ukulahleka kwe-dielectric kwezinto ze-EPR kuphakeme kakhulu kunokwe-XLPE kanye ne-WTR-XLPE.

3. Inqubo yokuvimbela ukuvuvukala

Inqubo yokuxhumanisa iqondene ngqo ne-polymer esetshenziswayo. Ukukhiqizwa kwama-polymer axhumene kuqala nge-matrix polymer bese kuba yi-stabilizers kanye nama-crosslinkers angeziwe ukuze kwakhiwe ingxube. Inqubo yokuxhumanisa inezela amaphuzu amaningi okuxhumanisa esakhiweni sama-molecule. Uma sesixhumene, uchungechunge lwama-molecule e-polymer luhlala lunwebeka, kodwa alukwazi ukuhlukaniswa ngokuphelele lube ukuncibilika koketshezi.

4. Izinto zokuvikela nokuvikela umqhubi

Ingqimba yokuvikela eqhuba kancane ikhishwa ebusweni bangaphandle bomqhubi kanye nokufakwa komoya ukuze ifane nensimu kagesi futhi igcine insimu kagesi enkabeni efakwe ikhebula. Le nto iqukethe izinga lobunjiniyela lezinto ezimnyama zekhabhoni ukuze ingqimba yokuvikela yekhebula ikwazi ukufeza ukuhanjiswa okuzinzile ngaphakathi kobubanzi obudingekayo.

Isikhathi sokuthunyelwe: Ephreli-12-2024