1. Ukubuka konke

Ngokuthuthuka okusheshayo kobuchwepheshe bolwazi nokuxhumana, izintambo ze-optical, njengezithwali eziyinhloko zokudlulisa ulwazi lwesimanje, zinezidingo eziphakeme kakhulu zokusebenza kanye nekhwalithi.I-Polybutylene terephthalate (PBT), njengepulasitiki yobunjiniyela be-thermoplastic esebenza kahle kakhulu, idlala indima ebalulekile ekukhiqizweni kwezintambo ze-optical. I-PBT yakhiwa yi-polymerization ye-condensation ye-dimethyl terephthalate (DMT) noma i-terephthalic acid (TPA) kanye ne-butanediol ngemva kokufakelwa. Ingenye yepulasitiki ezinhlanu zobunjiniyela ezisetshenziswa kabanzi futhi yasungulwa okokuqala yi-GE futhi yathuthukiswa ngezimboni ngawo-1970. Nakuba yaqala sekwephuzile, ithuthuke ngokushesha okukhulu. Ngenxa yokusebenza kwayo okuhle kakhulu, ukucutshungulwa okunamandla kanye nokusebenza okubiza kakhulu, isetshenziswa kabanzi ezintweni zikagesi, ezimotweni, kwezokuxhumana, ezintweni zasekhaya nakwezinye izinkambu. Ikakhulukazi ekukhiqizweni kwezintambo ze-optical, isetshenziswa kakhulu ekukhiqizweni kwamashubhu akhululekile e-fiber ye-optical futhi iwuhlobo olubalulekile lwezinto zekhebula ezisebenza kahle kakhulu ezintweni zokusetshenziswa zezintambo ze-optical.

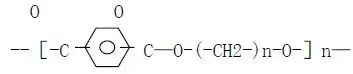

I-PBT iyi-polyester emhlophe efana nobisi ekhanyayo kancane kuya kwe-opaque e-semi-crystalline enokumelana okuhle kakhulu nokushisa kanye nokuqina kokucubungula. Isakhiwo sayo sama-molecule [(CH₂)₄OOCC₆H₄COO]n. Uma iqhathaniswa ne-PET, inamaqoqo amabili e-methylene ezingxenyeni zamaketanga, okwenza uchungechunge lwayo oluyinhloko lwama-molecule lube nesakhiwo esijikelezayo kanye nokuguquguquka okungcono. I-PBT ayimelani nama-asidi aqinile nama-alkali aqinile, kodwa ingamelana nezinyibilikisi eziningi eziphilayo futhi izobola emazingeni okushisa aphezulu. Ngenxa yezakhiwo zayo ezinhle kakhulu zomzimba, ukuzinza kwamakhemikhali kanye nokusebenza kokucubungula, i-PBT isibe yinto efanelekile yokwakha embonini yamaketanga optical futhi isetshenziswa kabanzi emikhiqizweni ehlukahlukene ye-PBT yamaketanga okuxhumana kanye namaketanga optical.

2. Izici zezinto ze-PBT

I-PBT ivame ukusetshenziswa ngendlela yokuxuba okuguquliwe. Ngokufaka izinto ezivimbela ilangabi, izinto zokuqinisa kanye nezinye izindlela zokuguqula, ukumelana kwayo nokushisa, ukufudumala kukagesi kanye nokuzivumelanisa nokucubungula kungathuthukiswa kakhulu. I-PBT inamandla aphezulu okusebenza, ukuqina okuhle kanye nokumelana nokuguguleka, futhi ingavikela ngempumelelo imicu yokukhanya engaphakathi kwekhebula lokukhanya ekulimaleni kokucindezeleka komshini. Njengenye yezinto ezisetshenziswayo ezivamile zezintambo zokukhanya, i-resin ye-PBT iqinisekisa ukuthi imikhiqizo yekhebula lokukhanya inokuguquguquka okuhle kanye nokuzinza ngenkathi igcina amandla esakhiwo.

Okwamanje, inokuqina okuqinile kwamakhemikhali futhi ingamelana nemidiya ehlukahlukene egqwalisayo, iqinisekisa ukusebenza okuzinzile kwesikhathi eside kwezintambo ezibonakalayo ezindaweni eziyinkimbinkimbi njengomswakama kanye nesifutho sikasawoti. Izinto ze-PBT zinokuqina okuhle kakhulu kokushisa futhi zingagcina ukusebenza okuzinzile ngisho nasezindaweni ezishisa kakhulu, okwenza zifaneleke ukusetshenziswa kwezintambo ezibonakalayo ezindaweni ezishisayo ezahlukene. Isebenza kahle kakhulu ekucubunguleni futhi ingakhiwa nge-extrusion, i-injection molding nezinye izindlela. Ifanele ukuhlanganiswa kwezintambo ezibonakalayo zezimo nezakhiwo ezahlukene futhi iyipulasitiki yobunjiniyela esebenza kahle esetshenziswa kabanzi ekukhiqizeni izintambo.

3. Ukusetshenziswa kwe-PBT kumakhebula e-Optical

Enkambisweni yokukhiqizwa kwekhebula le-optical, i-PBT isetshenziswa kakhulu ekukhiqizweni kwamapayipi akhululekileimicu yokukhanya. Amandla ayo aphezulu nokuqina kwayo kungasekela futhi kuvikele imicu ye-optical ngempumelelo, kuvimbele umonakalo obangelwa yizici zomzimba njengokugoba nokwelula. Ngaphezu kwalokho, izinto ze-PBT zinokumelana nokushisa okuhle kakhulu nokusebenza kokulwa nokuguga, okusiza ukuthuthukisa ukuzinza nokuthembeka kwezintambo ze-optical ngesikhathi sokusebenza isikhathi eside. Ingenye yezinto ezisetshenziswa kakhulu ze-PBT ezisetshenziswa ezintanjeni ze-optical njengamanje.

I-PBT ivame ukusetshenziswa njengesigxobo sangaphandle sezintambo ze-optical. Isigxobo asidingi nje kuphela ukuba namandla athile omshini ukuze sibhekane nezinguquko endaweni yangaphandle, kodwa futhi sidinga ukuba nokumelana okuhle kakhulu nokuguguleka, ukumelana nokugqwala kwamakhemikhali kanye nokumelana nokuguga kwe-UV ukuqinisekisa impilo yesevisi yekhebula le-optical ngesikhathi sokubekwa ngaphandle, ezindaweni ezimanzi noma zasemanzini. Isigxobo sekhebula le-optical sinezidingo eziphezulu zokusebenza kokucubungula kanye nokuzivumelanisa kwemvelo kwe-PBT, futhi i-resin ye-PBT ikhombisa ukuhambisana okuhle kokusetshenziswa.

Ezinhlelweni zokuxhumanisa ikhebula le-optical, i-PBT ingasetshenziswa futhi ukukhiqiza izingxenye ezibalulekile ezifana namabhokisi okuxhumanisa. Lezi zingxenye zidinga ukuhlangabezana nezidingo eziqinile zokuvala, ukuvimbela amanzi kanye nokumelana nesimo sezulu. Izinto ze-PBT, ezinezakhiwo zayo ezinhle kakhulu zomzimba kanye nokuqina kwesakhiwo, ziyindlela efanelekile kakhulu futhi zidlala indima ebalulekile yokusekela isakhiwo ohlelweni lwezinto zokusetshenziswa kwekhebula le-optical.

4. Izinyathelo Zokuqapha Zokucubungula

Ngaphambi kokucubungula ukubumba ngomjovo, i-PBT idinga ukomiswa ku-110℃ kuya ku-120℃ cishe amahora amathathu ukuze kususwe umswakama ofakwe emanzini futhi kugwenywe ukwakheka kwamabhamuza noma ukuqhekeka ngesikhathi sokucubungula. Izinga lokushisa lokubumba kufanele lilawulwe phakathi kuka-250℃ no-270℃, futhi izinga lokushisa lokubumba linconywa ukuthi ligcinwe ku-50℃ kuya ku-75℃. Ngenxa yokuthi izinga lokushisa lokushintsha kwengilazi le-PBT lingu-22℃ kuphela futhi izinga lokupholisa lishesha, isikhathi salo sokupholisa sifushane kakhulu. Ngesikhathi senqubo yokubumba ngomjovo, kuyadingeka ukuvimbela izinga lokushisa le-nozzle ukuthi lingabi phansi kakhulu, okungabangela ukuthi isiteshi sokugeleza sivalwe. Uma izinga lokushisa lebharele lidlula ku-275℃ noma izinto ezincibilikisiwe zihlala isikhathi eside kakhulu, kungabangela ukuwohloka kokushisa kanye nokuqhekeka.

Kunconywa ukusebenzisa isango elikhulu lokujova. Uhlelo lwe-hot runner akufanele lusetshenziswe. Isikhunta kufanele sigcine umphumela omuhle wokukhipha umoya. Izinto ze-PBT sprue eziqukethe ama-flame retardants noma i-glass fiber reinforcement azikhuthazwa ukuthi zisetshenziswe kabusha ukuze kugwenywe ukuwohloka kokusebenza. Uma umshini uvaliwe, umgqomo kufanele uhlanzwe ngesikhathi ngezinto ze-PE noma ze-PP ukuvimbela ukufakwa kwe-carbonization kwezinto ezisele. Lezi zinhlaka zokucubungula zinokubaluleka okusebenzayo kokuqondisa kubakhiqizi bezinto zokusetshenziswa zekhebula le-optical ekukhiqizweni kwezinto zekhebula ezinkulu.

5. Izinzuzo Zokusebenzisa

Ukusetshenziswa kwe-PBT ezintanjeni ze-optical kuthuthukise kakhulu ukusebenza kwezintambo ze-optical. Amandla ayo aphezulu kanye nokuqina kwayo kuthuthukisa ukumelana nomthelela kanye nokumelana nokukhathala kwentambo ye-optical, futhi kwandise impilo yayo yesevisi. Okwamanje, ukucutshungulwa okuhle kakhulu kwezinto ze-PBT kuthuthukise ukusebenza kahle kokukhiqiza futhi kunciphisa izindleko zokukhiqiza. Ukumelana okuhle kakhulu kokulwa nokuguga kanye nokugqwala kwamakhemikhali kwentambo ye-optical kuyenza ikwazi ukugcina ukusebenza okuzinzile isikhathi eside ezindaweni ezinzima, okuthuthukisa kakhulu ukuthembeka kanye nomjikelezo wokugcinwa komkhiqizo.

Njengesigaba esibalulekile ezintweni zokusetshenziswa zezintambo ze-optical, i-PBT resin idlala indima ezinhlotsheni eziningi zesakhiwo futhi ingenye yamapulasitiki obunjiniyela be-thermoplastic abakhiqizi bezintambo ze-optical abawabeka kuqala lapho bekhetha izinto zekhebula.

6. Iziphetho namathemba

I-PBT isibe yinto ebalulekile kakhulu emkhakheni wokukhiqiza izintambo ze-optical ngenxa yokusebenza kwayo okuvelele ezimpahleni zemishini, ukuzinza kokushisa, ukumelana nokugqwala kanye nokucutshungulwa. Esikhathini esizayo, njengoba imboni yokuxhumana kwe-optical iqhubeka nokuthuthuka, izidingo eziphakeme zizobekwa phambili ekusebenzeni kwezinto ezibonakalayo. Imboni ye-PBT kufanele iqhubeke nokukhuthaza ubuchwepheshe obusha kanye nokuthuthukiswa kokuvikelwa kwemvelo okuluhlaza, ithuthukise ukusebenza kwayo okuphelele kanye nokusebenza kahle kokukhiqiza. Ngenkathi ihlangabezana nezidingo zokusebenza, ukunciphisa ukusetshenziswa kwamandla kanye nezindleko zezinto kuzosiza i-PBT ukuthi idlale indima ebaluleke kakhulu ezintanjeni ze-optical kanye nohlu olubanzi lwezinkambu zohlelo lokusebenza.

Isikhathi sokuthunyelwe: Juni-30-2025