Ukusebenza kwezinto zokufaka ugesi kuthinta ngqo ikhwalithi, ukusebenza kahle kokucubungula kanye nobubanzi bokusetshenziswa kwezintambo nezintambo. Ukusebenza kwezinto zokufaka ugesi kuthinta ngqo ikhwalithi, ukusebenza kahle kokucubungula kanye nobubanzi bokusetshenziswa kwezintambo nezintambo.

1. Izintambo nezintambo ze-polyvinyl chloride ze-PVC

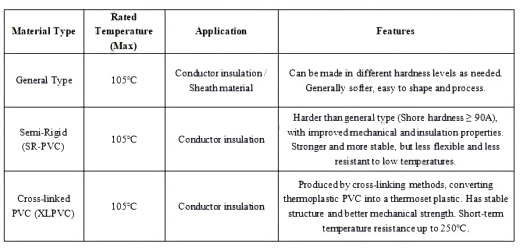

I-Polyvinyl chloride (ezobizwa ngokuthiI-PVCIzinto zokuvikela ugesi ziyingxube lapho iziqinisi, amapulasitiki, izinto ezivimbela umlilo, izinto zokugcoba nezinye izithasiselo zengezwa khona ku-PVC powder. Ngokwezinhlelo zokusebenza ezahlukene kanye nezidingo ezihlukile zezintambo namakhebula, ifomula ilungiswa ngokufanele. Ngemva kwamashumi eminyaka yokukhiqizwa nokusetshenziswa, ubuchwepheshe bokukhiqiza nokucubungula be-PVC manje sebuvuthiwe kakhulu. Izinto zokuvikela ugesi ze-PVC zinezinhlelo zokusebenza eziningi kakhulu emkhakheni wezintambo namakhebula futhi zinezici ezihlukile:

A. Ubuchwepheshe bokukhiqiza buvuthiwe, kulula ukububumba nokubucubungula. Uma buqhathaniswa nezinye izinhlobo zezinto zokuvikela ikhebula, abugcini nje ngokuba nezindleko eziphansi, kodwa futhi bungalawula ngempumelelo umehluko wombala, ukucwebezela, ukuphrinta, ukusebenza kahle kokucubungula, ubumnene nobunzima bomphezulu wentambo, ukunamathela komqhubi, kanye nezakhiwo zemishini nezomzimba kanye nezakhiwo zikagesi zentambo ngokwayo.

B. Isebenza kahle kakhulu ekuvimbeleni ilangabi, ngakho-ke izintambo ezivikelwe yi-PVC zingahlangabezana kalula namazinga okuvimbeleni ilangabi ashiwo yizindinganiso ezahlukahlukene.

C. Ngokuphathelene nokumelana nokushisa, ngokusebenzisa ukwenza ngcono nokuthuthukisa amafomula ezinto ezibonakalayo, izinhlobo ezisetshenziswa kakhulu zokufakelwa kwe-PVC zifaka phakathi izigaba ezintathu ezilandelayo:

Ngokuphathelene ne-voltage elinganisiwe, ivame ukusetshenziswa emazingeni e-voltage alinganiswe ku-1000V AC nangaphansi, futhi ingasetshenziswa kabanzi ezimbonini ezifana nezinto zasekhaya, izinsimbi namamitha, ukukhanyisa, kanye nokuxhumana kwenethiwekhi.

I-PVC inezinkinga ezithile ezivimbela ukusetshenziswa kwayo:

A. Ngenxa yokuqukethwe kwayo okuphezulu kwe-chlorine, izokhipha intuthu enkulu ejiyile uma isha, okungabangela ukuminyana, kuthinte ukubonakala, futhi kukhiqize ezinye izinto ezibangela umdlavuza kanye negesi ye-HCl, okubangela umonakalo omkhulu emvelweni. Ngokuthuthuka kobuchwepheshe bokukhiqiza izinto zokufaka uthuli ezingenayo i-halogen, ukufaka kancane kancane uthuli lwe-PVC sekuye kwaba umkhuba ongenakugwenywa ekuthuthukisweni kwezintambo.

B. Ukufakwa kwe-PVC okuvamile kunokumelana okuncane nama-acid nama-alkali, uwoyela wokushisa, kanye nezinyibilikisi eziphilayo. Ngokwesimiso samakhemikhali esithi i-like dissolves like, izintambo ze-PVC zithambekele kakhulu ekulimaleni nasekuqhekekeni endaweni ethile okukhulunywe ngayo. Kodwa-ke, ngenxa yokusebenza kwayo okuhle kakhulu kokucubungula kanye nezindleko eziphansi. Izintambo ze-PVC zisasetshenziswa kabanzi ezintweni zasendlini, ezitsheni zokukhanyisa, emishinini, ezitsheni nasezilinganisweni, ekuxhumaneni kwenethiwekhi, ezintanjeni zokwakha nakwezinye izinkambu.

2. Izintambo nezintambo ze-polyethylene ezixhumene

I-Cross-linked PE (ezobizwa ngokuthi i-Cross-linked PE)I-XLPE) uhlobo lwe-polyethylene olungaguquka lusuke esakhiweni sama-molecule esiqondile luye esakhiweni esinezinhlangothi ezintathu esinezinhlangothi ezintathu ngaphansi kwezimo ezithile ngaphansi kwesenzo semisebe enamandla aphezulu noma ama-agent axhumanisayo. Ngesikhathi esifanayo, luguquka lusuke ku-thermoplastic luye ku-thermosetting plastic enganyibiliki.

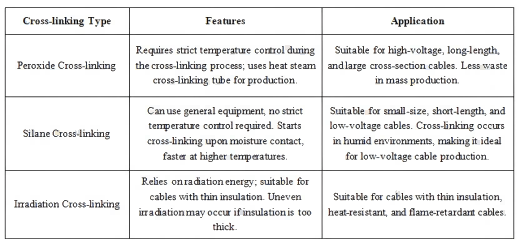

Njengamanje, ekusetshenzisweni kokufakwa kwe-wire kanye ne-cable, kunezindlela ezintathu zokuxhumanisa:

A. Ukuxhumanisa nge-peroxide: Kuhilela ukusebenzisa i-polyethylene resin kuqala ngokuhlanganiswa nama-agent afanele okuxhumanisa kanye nama-antioxidants, bese kungezwa ezinye izingxenye njengoba kudingeka ukukhiqiza izinhlayiya zengxube ye-polyethylene ezixhumene. Ngesikhathi senqubo yokukhipha, ukuxhumanisa kwenzeka ngamapayipi okuxhumanisa nge-hot steam.

B. Ukuxhumanisa i-Silane (ukuxhumanisa amanzi afudumele): Lena futhi indlela yokuxhumanisa ngamakhemikhali. Indlela yayo eyinhloko ukuxhumanisa i-organosiloxane ne-polyethylene ngaphansi kwezimo ezithile,

futhi izinga lokuxhumanisa ngokuvamile lingafinyelela cishe ku-60%.

C. Ukuxhumanisa ngemisebe: Kusebenzisa imisebe enamandla aphezulu njenge-R-rays, imisebe ye-alpha, kanye nemisebe ye-electron ukuze kusebenze ama-athomu e-carbon kuma-macromolecule e-polyethylene futhi kubangele ukuxhumanisa ngemisebe. Imisebe enamandla aphezulu evame ukusetshenziswa ezintanjeni nasezintanjeni imisebe ye-electron ekhiqizwa yizisheshisi ze-electron. Njengoba lokhu kuxhumanisa ngemisebe kuncike emandleni angokwenyama, kungokwe-physical cross-linking.

Izindlela ezintathu ezahlukene zokuxhumanisa ezingenhla zinezici kanye nezinhlelo zokusebenza ezihlukile:

Uma kuqhathaniswa ne-thermoplastic polyethylene (PVC), i-XLPE insulation inezinzuzo ezilandelayo:

A. Kuthuthukise ukumelana nokuguquguquka kokushisa, kwathuthukisa izakhiwo zemishini emazingeni okushisa aphezulu, futhi kwathuthukisa ukumelana nokuqhekeka kokucindezeleka kwemvelo kanye nokuguga kokushisa.

B. Ithuthukise ukuzinza kwamakhemikhali kanye nokumelana nesinyibilikisi, yanciphisa ukugeleza kokubanda, futhi ngokuyisisekelo yagcina ukusebenza kukagesi kokuqala. Izinga lokushisa lokusebenza kwesikhathi eside lingafinyelela ku-125℃ kanye no-150℃. Intambo nekhebula le-polyethylene elihlanganisiwe elifakwe i-cross-linked polyethylene nakho kuthuthukisa ukumelana ne-short-circuit, futhi ukumelana kwayo nokushisa kwesikhathi esifushane kungafinyelela ku-250℃, ngezintambo nezintambo ezinobukhulu obufanayo, amandla okuphatha amandla kagesi e-cross-linked polyethylene makhulu kakhulu.

C. Inezakhiwo ezinhle kakhulu zomshini, ezingangeni manzi kanye nezingamelani nemisebe, ngakho-ke isetshenziswa kabanzi emikhakheni eyahlukahlukene. Njenge: izintambo zokuxhuma zangaphakathi zezinto zikagesi, izintambo zemoto, izintambo zokukhanyisa, izintambo zokulawula isignali ezisebenzisa amandla aphansi ezimotweni, izintambo zesitimela, izintambo kanye nezintambo zesitimela esingaphansi komhlaba, izintambo zokuvikela imvelo zezimayini, izintambo zasemanzini, izintambo zokubeka amandla enuzi, izintambo ze-TV ezisebenzisa amandla aphezulu okudubula nge-X-RAY, kanye nezintambo zokudlulisa amandla kanye nezintambo, njll.

Izintambo nezintambo ezifakwe ugesi ze-XLPE zinezinzuzo ezibalulekile, kodwa futhi zinezinkinga ezithile ezivimbela ukusetshenziswa kwazo:

A. Ukusebenza kabi kokunamathela okumelana nokushisa. Lapho kucutshungulwa futhi kusetshenziswa izintambo ezingaphezu kwezinga lokushisa elilinganiselwe, kulula ukuthi izintambo zinamathele komunye nomunye. Ezimweni ezimbi kakhulu, kungaholela ekulimaleni kokufakwa kwe-insulation kanye nama-short circuits.

B. Ukumelana nokushisa okubi. Emazingeni okushisa angaphezu kuka-200℃, ukufudumala kwezintambo kuba mnene kakhulu. Uma kucindezelwa noma kushayisana ngamandla angaphandle, kungabangela ukuthi izintambo zisike futhi zifinyelele kumjikelezo omfushane.

C. Kunzima ukulawula umehluko wombala phakathi kwamaqoqo. Izinkinga ezifana nokuklwebheka, ukuba mhlophe kanye nokuqhekeka kwezinhlamvu eziphrintiwe zivame ukwenzeka ngesikhathi sokucubungula

D. Ukufakwa kwe-XLPE okunezinga lokumelana nokushisa elingu-150℃ akunawo nhlobo ama-halogen futhi kungadlula isivivinyo sokushiswa kwe-VW-1 ngokuhambisana namazinga e-UL1581, kuyilapho kugcinwa izakhiwo ezinhle kakhulu zemishini kanye nogesi. Kodwa-ke, kusenezingqinamba ezithile kubuchwepheshe bokukhiqiza futhi izindleko ziphezulu.

3. Izintambo zerabha ze-silicone kanye nezintambo

Ama-molecule e-polymer erabha ye-silicone ayizakhiwo zamaketanga ezakhiwe yizibopho ze-SI-O (i-silicon-oxygen). Isibopho se-SI-O singama-443.5KJ/MOL, okuphakeme kakhulu kunamandla esibopho se-CC (355KJ/MOL). Izintambo eziningi zerabha ye-silicone kanye nezintambo zikhiqizwa ngokusebenzisa izinqubo zokukhipha ezibandayo kanye nezinqubo zokushisa okuphezulu. Phakathi kwezintambo nezintambo zerabha zokwenziwa ezahlukahlukene, ngenxa yesakhiwo sayo esiyingqayizivele sama-molecule, irabha ye-silicone isebenza kahle kakhulu uma kuqhathaniswa nezinye irabha ezivamile.

A. Ithambile kakhulu, inokuqina okuhle, ayinaphunga futhi ayinabo ubuthi, futhi ayesabi amazinga okushisa aphezulu futhi ingamelana nokubanda okukhulu. Izinga lokushisa lokusebenza lisukela ku--90 kuya ku-300℃. Irabha ye-silicone inokumelana nokushisa okungcono kakhulu kunerabha evamile. Ingasetshenziswa njalo ku-200℃ kanye nesikhathi esithile ku-350 ℃.

B. Ukumelana nesimo sezulu okuhle kakhulu. Ngisho nangemva kokuchayeka isikhathi eside emisebeni ye-ultraviolet nakwezinye izimo zezulu, izakhiwo zayo zomzimba ziye zashintsha kancane.

C. Irabha ye-silicone inokumelana okuphezulu kakhulu futhi ukumelana kwayo kuhlala kuzinzile phezu kwamazinga okushisa ahlukahlukene kanye namaza.

Okwamanje, irabha ye-silicone inokumelana okuhle kakhulu nokukhishwa kwe-corona okunamandla aphezulu kanye nokukhishwa kwe-arc. Izintambo nezintambo ezifakwe i-silicone ngerabha ezifakwe i-silicone zinezinzuzo eziningi ezingenhla futhi zisetshenziswa kabanzi ezintanjeni zamadivayisi ane-voltage ephezulu zamathelevishini, izintambo ezingamelana nokushisa okuphezulu zama-oven e-microwave, izintambo zezitofu zokungenisa, izintambo zamabhodwe ekhofi, ama-lead ezibani, imishini ye-UV, izibani ze-halogen, izintambo zokuxhuma zangaphakathi zama-oven namafeni, ikakhulukazi emkhakheni wezinto zasendlini ezincane.

Kodwa-ke, amanye amaphutha ayo nawo anciphisa ukusetshenziswa kwayo kabanzi. Isibonelo:

A. Ukumelana nokuklebhuka okubi. Ngesikhathi sokucubungula noma ukusebenzisa, kulula ukulimaza ngenxa yokucindezelwa kwamandla angaphandle, ukuklwebheka nokugaya, okungase kubangele umjikelezo omfushane. Indlela yokuvikela yamanje ukufaka ungqimba lwefayibha yengilazi noma ifayibha ye-polyester eshisa kakhulu eboshwe ngaphandle kwe-silicone insulation. Kodwa-ke, ngesikhathi sokucubungula, kusadingeka ukugwema ukulimala okubangelwa ukucindezelwa kwamandla angaphandle ngangokunokwenzeka.

B. I-ejenti ye-vulcanizing esetshenziswa kakhulu njengamanje ekubunjweni kwe-vulcanization iphindwe kabili, kabili, kane. Le ejenti ye-vulcanizing iqukethe i-chlorine. Ama-ejenti e-vulcanizing angenayo i-halogen ngokuphelele (njenge-platinum vulcanizing) anezidingo eziqinile zokushisa kwendawo yokukhiqiza futhi ayabiza. Ngakho-ke, lapho kucutshungulwa ama-wire harnesses, amaphuzu alandelayo kufanele aqashelwe: ingcindezi yesondo lokucindezela akufanele ibe phezulu kakhulu. Kungcono ukusebenzisa izinto zerabha ukuvimbela ukuqhekeka ngesikhathi senqubo yokukhiqiza, okungaholela ekumelaneni okungekuhle kwengcindezi.

4. Intambo yerabha ye-ethylene propylene diene monomer (EPDM) (XLEPDM) exhumene ne-cross-linked

Irabha ye-ethylene propylene diene monomer (EPDM) exhumene ne-cross-linked iyi-terpolymer ye-ethylene, i-propylene kanye ne-diene engaxhunywanga, exhumene ngezindlela zamakhemikhali noma zokukhanya. I-Cross-linked EPDM raber insulated ihlanganisa izinzuzo zombili i-polyolefin insulated wire kanye ne-rubber evamile insulated wire:

A. Ithambile, iyaguquguquka, iyanwebeka, ayinamatheli emazingeni okushisa aphezulu, imelana nokuguga isikhathi eside, futhi imelana nezimo zezulu ezinzima (-60 kuya ku-125℃).

B. Ukumelana ne-ozone, ukumelana ne-UV, ukumelana nokushisa kukagesi, kanye nokumelana nokugqwala kwamakhemikhali.

C. Ukumelana kwamafutha kanye ne-solvent kufana nokwe-insulation yerabha ye-chloroprene yenhloso ejwayelekile. Icutshungulwa ngemishini ejwayelekile yokukhipha ukushisa futhi kusetshenziswa i-irradiation cross-linking, okulula ukuyicubungula futhi engabizi kakhulu. Izintambo ezifakwe irabha ze-ethylene propylene diene monomer (EPDM) ezifakwe i-cross-linked zinezinzuzo eziningi ezishiwo ngenhla futhi zisetshenziswa kabanzi emikhakheni efana nama-compressor leads esiqandisini, ama-motor leads angangeni manzi, ama-transformer leads, izintambo eziphathwayo ezimayini, ukubhoboza, izimoto, amadivayisi ezokwelapha, imikhumbi, kanye nezintambo zangaphakathi ezijwayelekile zezinto zikagesi.

Izinkinga eziyinhloko zezintambo ze-XLEPDM yilezi:

A. Njengezintambo ze-XLPE ne-PVC, ayinawo amandla okudabuka.

B. Ukunamathela okubi kanye nokuzinamathelisa kuthinta ukucutshungulwa okulandelayo.

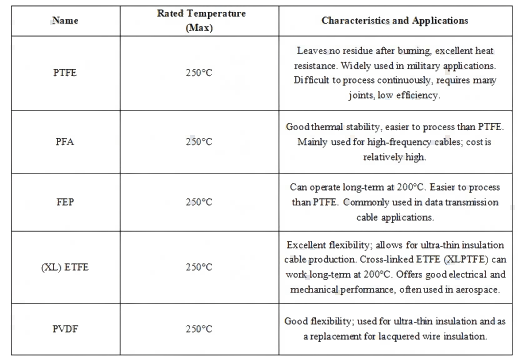

5. Izintambo nezintambo ze-fluoroplastic

Uma kuqhathaniswa nezintambo ze-polyethylene ezivamile kanye ne-polyvinyl chloride, izintambo ze-fluoroplastic zinezici ezilandelayo ezivelele:

A. Ama-fluoroplastic amelana nokushisa okuphezulu anokuqina okungavamile kokushisa, okwenza izintambo ze-fluoroplastic zikwazi ukuzivumelanisa nezimo zokushisa okuphezulu ezisukela ku-150 kuya ku-250 degrees Celsius. Ngaphansi kwesimo sama-conductors anendawo efanayo yokunqamula, izintambo ze-fluoroplastic zingadlulisela ugesi omkhulu ovumelekile, ngaleyo ndlela zandise kakhulu ububanzi bokusetshenziswa kwalolu hlobo lwentambo evalekile. Ngenxa yalesi sici esiyingqayizivele, izintambo ze-fluoroplastic zivame ukusetshenziselwa izintambo zangaphakathi kanye nezintambo ze-lead ezindizeni, emikhunjini, ezitsheni zokushisa okuphezulu, kanye nemishini kagesi.

B. Ukumelana okuhle nomlilo: Ama-fluoroplastics ane-oxygen index ephezulu, futhi uma evutha, ububanzi bokusabalala komlilo buncane, okwenza kube nentuthu encane. Ucingo olwenziwe ngalo lufanelekela amathuluzi nezindawo ezinezidingo eziqinile zokumelana nomlilo. Isibonelo: amanethiwekhi amakhompyutha, imigwaqo engaphansi komhlaba, izimoto, izakhiwo eziphakeme kanye nezinye izindawo zomphakathi, njll. Uma umlilo uqalile, abantu bangaba nesikhathi sokuphuma ngaphandle kokushayiswa yintuthu eningi, ngaleyo ndlela bathole isikhathi esiyigugu sokutakula.

C. Ukusebenza kahle kakhulu kukagesi: Uma kuqhathaniswa ne-polyethylene, ama-fluoroplastics anokuqina okuphansi kwe-dielectric. Ngakho-ke, uma kuqhathaniswa nezintambo ze-coaxial zezakhiwo ezifanayo, izintambo ze-fluoroplastic azinawo amandla amaningi futhi zifaneleka kakhulu ekudlulisweni kwesignali yemvamisa ephezulu. Namuhla, ukwanda kwemvamisa yokusetshenziswa kwekhebula sekuyinto evamile. Okwamanje, ngenxa yokumelana nokushisa okuphezulu kwama-fluoroplastics, avame ukusetshenziswa njengezintambo zangaphakathi zemishini yokudlulisa nokuxhumana, ama-jumpers phakathi kwe-feeders yokudlulisa engenantambo kanye nama-transmitter, kanye nezintambo zevidiyo nezomsindo. Ngaphezu kwalokho, izintambo ze-fluoroplastic zinamandla amahle e-dielectric kanye nokumelana nokushisa, okwenza zifaneleke ukusetshenziswa njengezintambo zokulawula zezinsimbi ezibalulekile namamitha.

D. Izakhiwo eziphelele zemishini namakhemikhali: Ama-fluoroplastic anamandla aphezulu okubopha amakhemikhali, ukuzinza okuphezulu, cishe awathinteki yizinguquko zokushisa, futhi anokumelana okuhle kakhulu nokuguga kwesimo sezulu kanye namandla emishini. Futhi awathinteki yizinhlobo ezahlukene zama-acid, ama-alkali kanye nezinyibilikisi eziphilayo. Ngakho-ke, afaneleka ezindaweni ezinezinguquko ezinkulu zesimo sezulu kanye nezimo ezigqwalisayo, njengamakhemikhali e-petrochemical, ukuhluzwa kwamafutha, kanye nokulawulwa kwezinsimbi zemithombo yamafutha.

E. Kwenza kube lula ukuxhumeka kokushisela Ezintweni zikagesi, ukuxhumeka okuningi kwenziwa ngokushisela. Ngenxa yezinga eliphansi lokuncibilika kwamapulasitiki ajwayelekile, avame ukuncibilika kalula emazingeni okushisa aphezulu, okudinga amakhono okushisela anekhono. Ngaphezu kwalokho, amanye amaphuzu okushisela adinga isikhathi esithile sokushisela, okuyisona sizathu esenza izintambo ze-fluoroplastic zithandwa. Njengokuxhuma kwangaphakathi kwemishini yokuxhumana kanye nezinsimbi zikagesi.

Yiqiniso, ama-fluoroplastic asenezinkinga ezithile ezinciphisa ukusetshenziswa kwawo:

A. Intengo yezinto zokusetshenziswa iphezulu. Njengamanje, ukukhiqizwa kwasekhaya kusancike kakhulu ekungenisweni kwamanye amazwe (iDaikin yaseJapan kanye neDuPont yase-United States). Nakuba ama-fluoroplastic asekhaya athuthuke ngokushesha eminyakeni yamuva nje, izinhlobo zokukhiqiza zisalokhu zodwa. Uma kuqhathaniswa nezinto ezingenisiwe, kusenesikhala esithile ekuzinzeni kokushisa kanye nezinye izakhiwo eziphelele zezinto.

B. Uma kuqhathaniswa nezinye izinto zokuvikela ukushisa, inqubo yokukhiqiza inzima kakhulu, ukusebenza kahle kokukhiqiza kuphansi, izinhlamvu eziphrintiwe zivame ukuwa, futhi ukulahlekelwa kukhulu, okwenza izindleko zokukhiqiza ziphakame kakhulu.

Ekuphetheni, ukusetshenziswa kwazo zonke izinhlobo zezinto zokuvikela ezishiwo ngenhla, ikakhulukazi izinto zokuvikela ezikhethekile ezishisa kakhulu ezinokumelana nokushisa okungaphezu kuka-105℃, kusesesikhathini sokushintsha eShayina. Kungakhathaliseki ukuthi ukukhiqizwa kwentambo noma ukucubungula izintambo zentambo, akukhona nje inqubo evuthiwe, kodwa futhi nenqubo yokuqonda ngokunengqondo izinzuzo kanye nokungalungi kwalolu hlobo lwentambo.

Isikhathi sokuthunyelwe: Meyi-27-2025