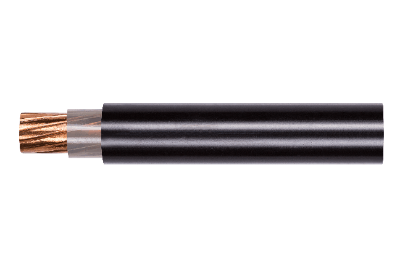

I-Polyethylene (PE) isetshenziswa kabanzi ezimbonini.ukuvala nokuvala izintambo zikagesi nezintambo zokuxhumanangenxa yamandla ayo amahle kakhulu okusebenza, ukuqina, ukumelana nokushisa, ukufudumala, kanye nokuqina kwamakhemikhali. Kodwa-ke, ngenxa yezici zesakhiwo se-PE uqobo, ukumelana kwayo nokuqhekeka kokucindezeleka kwemvelo kuphansi kakhulu. Le nkinga iba sobala kakhulu lapho i-PE isetshenziswa njenge-sheath yangaphandle yezintambo ezivikelwe ngezikhali ezinkulu.

1. Indlela Yokuqhekeka Kwesigxobo Se-PE

Ukuqhekeka kwe-PE sheath kwenzeka kakhulu ezimweni ezimbili:

a. Ukuqhekeka Kwengcindezi Yemvelo: Lokhu kubhekisela esimweni lapho igobolondo liqhekeka khona ngenxa yokucindezeleka okuhlangene noma ukuchayeka ezintweni zemvelo ngemva kokufakwa nokusebenza kwekhebula. Kubangelwa kakhulu ukucindezeleka kwangaphakathi ngaphakathi kwegobolondo kanye nokuchayeka isikhathi eside ezintweni ezimanzi ezibandayo. Ucwaningo olunzulu ngokuguqulwa kwezinto luye lwaxazulula kakhulu lolu hlobo lokuqhekeka.

b. Ukuqhekeka Kokucindezeleka Kwemishini: Lokhu kwenzeka ngenxa yokuntuleka kwesakhiwo kukhebula noma izinqubo zokukhipha isheya ezingafanele, okuholela ekugxilweni okukhulu kokucindezeleka kanye nokuqhekeka okubangelwa ukuguqulwa ngesikhathi sokufakwa kwekhebula. Lolu hlobo lokuqhekeka lubonakala kakhulu ezisheya zangaphandle zezintambo ezivikelwe ngetheyiphu yensimbi enezingxenye ezinkulu.

2. Izimbangela Zokuqhekeka Kwesigxobo Se-PE kanye Nezinyathelo Zokuthuthukisa

2.1 Ithonya LekhebulaItheyiphu YensimbiIsakhiwo

Ezintanjeni ezine-diameter enkulu yangaphandle, ungqimba oluvikelwe ngezikhali luvame ukwakhiwa ngama-tape wrap ensimbi anezingqimba ezimbili. Kuye ngobubanzi bangaphandle bekhebula, ubukhulu be-tape yensimbi buyahlukahluka (0.2mm, 0.5mm, kanye no-0.8mm). Ama-tape ensimbi avikelwe ngezikhali anokuqina okuphezulu kanye ne-plasticity ephansi, okuholela ekuhlukaneni okukhulu phakathi kwezingqimba eziphezulu nezingezansi. Ngesikhathi sokukhipha, lokhu kubangela umehluko omkhulu ekujikeni kwe-sheath phakathi kwezingqimba eziphezulu nezingezansi zobuso be-armored layer. Izindawo ze-sheath ezincane emaphethelweni e-tape yensimbi yangaphandle zithola ukugxilisa okukhulu kakhulu futhi yizindawo eziyinhloko lapho kwenzeka khona ukuqhekeka esikhathini esizayo.

Ukuze kuncishiswe umthelela wetheyiphu yensimbi evikelwe esigxotsheni sangaphandle, ungqimba lokubopha olunobukhulu obuthile luyasongwa noma lukhishwe phakathi kwetheyiphu yensimbi nesigxobo se-PE. Lolu ngqimba lokubopha kufanele lube luqinile ngokulinganayo, ngaphandle kwemibimbi noma ukuvela. Ukwengezwa kwengqimba yokubopha kuthuthukisa ukushelela phakathi kwezingqimba ezimbili zetheyiphu yensimbi, kuqinisekisa ukujiya kwesigxobo se-PE okufanayo, futhi, kuhlangene nokufinyela kwesigxobo se-PE, kunciphisa ukucindezeleka kwangaphakathi.

I-ONEWORLD inikeza abasebenzisi ubukhulu obuhlukahlukene be-izinto ezivikelwe nge-tape yensimbi ehlanganisiweukuhlangabezana nezidingo ezahlukene.

2.2 Umthelela Wenqubo Yokukhiqiza Izintambo

Izinkinga eziyinhloko ngenqubo yokukhipha ama-sheath amakhulu ekhebula angaphandle ahlomile ububanzi bawo ukupholisa okunganele, ukulungiswa okungafanele kwesikhunta, kanye nesilinganiso sokwelula ngokweqile, okuholela ekucindezelekeni okukhulu kwangaphakathi ngaphakathi kwe-sheath. Izintambo ezinkulu, ngenxa yama-sheath azo amakhulu futhi abanzi, zivame ukubhekana nemikhawulo ebudeni nasebuningini bemifudlana yamanzi emigqeni yokukhiqiza i-extrusion. Ukupholisa kusuka ngaphezu kwama-degree Celsius angu-200 ngesikhathi sokukhipha kuya ekushiseni kwegumbi kudala izinselele. Ukupholisa okunganele kuholela emfudlaneni othambile eduze kwesendlalelo se-armor, okubangela ukuklwebheka ebusweni be-sheath lapho ikhebula ligoqiwe, ekugcineni okuholela ekuqhekekeni okungenzeka kanye nokuphuka ngesikhathi sokubekwa kwekhebula ngenxa yamandla angaphandle. Ngaphezu kwalokho, ukupholisa okunganele kunegalelo ekwandeni kwamandla angaphakathi okuncipha ngemva kokubopha, okuphakamisa ingozi yokuqhekeka kwe-sheath ngaphansi kwamandla amakhulu angaphandle. Ukuqinisekisa ukupholisa okwanele, kunconywa ukwandisa ubude noma ivolumu yemifudlana yamanzi. Ukwehlisa isivinini sokukhipha ngenkathi kugcinwa ipulasitiki efanele ye-sheath kanye nokuvumela isikhathi esanele sokupholisa ngesikhathi sokubopha kubalulekile. Ngaphezu kwalokho, uma sibheka i-polyethylene njenge-polymer ekristalu, indlela yokupholisa yokunciphisa izinga lokushisa ehlukaniswe ngezigaba, kusukela ku-70-75°C kuya ku-50-55°C, futhi ekugcineni kuya ekushiseni kwegumbi, kusiza ekunciphiseni ukucindezeleka kwangaphakathi ngesikhathi senqubo yokupholisa.

2.3 Ithonya Le-Coiling Radius Ekugoqeni Kwekhebula

Ngesikhathi sokugoqa ikhebula, abakhiqizi banamathela ezindinganisweni zemboni zokukhetha ama-reel okulethwa afanele. Kodwa-ke, ukwamukela ubude obude bokulethwa kwezintambo ezinkulu zangaphandle kudala izinselele ekukhetheni ama-reel afanele. Ukuze kuhlangatshezwane nobude obubekiwe bokulethwa, abanye abakhiqizi banciphisa ububanzi bemigqomo yereel, okuholela ekungabikho kwe-radii yokugoba eyanele yekhebula. Ukugoba ngokweqile kuholela ekushintsheni kwezingqimba zezivikelo, okubangela amandla amakhulu okugunda esigxotsheni. Ezimweni ezimbi kakhulu, ama-burrs ensimbi evikelwe angabhoboza ungqimba lokusika, angene ngqo esigxotsheni futhi abangele imifantu noma imifantu emaphethelweni e-strip yensimbi. Ngesikhathi sokubekwa kwekhebula, amandla okugoba nokudonsa ohlangothini abangela ukuthi i-sheath iqhekeke kulezi zimfa, ikakhulukazi ezingcingweni eziseduze nezingqimba zangaphakathi ze-reel, okwenza kube lula ukuphuka.

2.4 Umthelela Wendawo Yokwakha Nokufaka Esakhiweni

Ukuze kwenziwe ukwakhiwa kwekhebula kube ngokwejwayelekile, kuyalulekwa ukunciphisa isivinini sokubekwa kwekhebula, ugweme ukucindezela okukhulu ohlangothini, ukugoba, ukudonsa amandla, kanye nokushayisana kwendawo, ukuqinisekisa indawo yokwakha ephucukile. Kungcono, ngaphambi kokufakwa kwekhebula, vumela ikhebula liphumule ku-50-60°C ukuze likhulule ukucindezeleka kwangaphakathi kusuka esikhwameni. Gwema ukuvezwa isikhathi eside kwezintambo elangeni eliqondile, njengoba amazinga okushisa ahlukene ezinhlangothini ezahlukene zekhebula angaholela ekugxilweni kokucindezeleka, okwandisa ingozi yokuqhekeka kwesikhwama ngesikhathi sokufakwa kwekhebula.

Isikhathi sokuthunyelwe: Disemba 18-2023