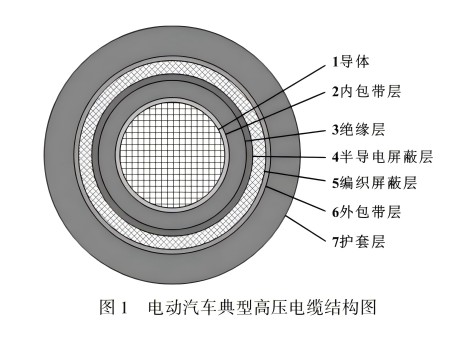

Isikhathi esisha semboni yezimoto zamandla amasha sihambisana nomsebenzi ophindwe kabili wokuguqulwa kwezimboni kanye nokuthuthukiswa kanye nokuvikelwa kwemvelo yasemkhathini, okuqhuba kakhulu ukuthuthukiswa kwezimboni kwezintambo ezinamandla aphezulu kanye nezinye izesekeli ezihlobene zezimoto zikagesi, futhi abakhiqizi bezintambo kanye nezinhlangano zezitifiketi batshale amandla amaningi ocwaningweni nasekuthuthukisweni kwezintambo ezinamandla aphezulu zezimoto zikagesi. Izintambo ezinamandla aphezulu zezimoto zikagesi zinezidingo zokusebenza okuphezulu kuzo zonke izici, futhi kufanele zihlangabezane nezindinganiso ze-RoHSb, izidingo ezijwayelekile ze-UL94V-0 ezivimbela ilangabi kanye nokusebenza okuthambile. Leli phepha lethula izinto zokwakha kanye nobuchwepheshe bokulungiselela izintambo ezinamandla aphezulu zezimoto zikagesi.

1. Izinto zekhebula le-voltage ephezulu

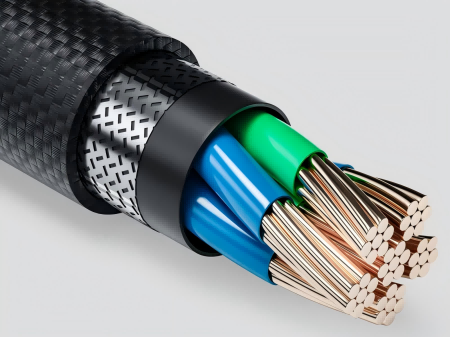

(1) Izinto zomqhubi wekhebula

Njengamanje, kunezinto ezimbili eziyinhloko zesendlalelo somqhubi wekhebula: ithusi ne-aluminium. Izinkampani ezimbalwa zicabanga ukuthi i-aluminium core inganciphisa kakhulu izindleko zazo zokukhiqiza, ngokungeza ithusi, insimbi, i-magnesium, i-silicon nezinye izinto ngokusekelwe ezintweni ze-aluminium ezihlanzekile, ngezinqubo ezikhethekile ezifana nokuhlanganiswa nokwelashwa kokufakelwa, ukuthuthukisa ukuhanjiswa kukagesi, ukusebenza kokugoba kanye nokumelana nokugqwala kwekhebula, ukuze kuhlangatshezwane nezidingo zomthamo ofanayo womthwalo, ukufeza umphumela ofanayo nabaqhubi be-core yethusi noma okungcono nakakhulu. Ngakho-ke, izindleko zokukhiqiza zilondolozwa kakhulu. Kodwa-ke, amabhizinisi amaningi asabheka ithusi njengento eyinhloko yesendlalelo somqhubi, okokuqala, ukumelana kwethusi kuphansi, bese iningi lokusebenza kwethusi kungcono kunokwe-aluminium ezingeni elifanayo, njengomthamo omkhulu wokuthwala wamanje, ukulahlekelwa yi-voltage ephansi, ukusetshenziswa kwamandla aphansi kanye nokuthembeka okuqinile. Njengamanje, ukukhethwa kwabaqhubi ngokuvamile kusebenzisa abaqhubi abathambile abajwayelekile abayisithupha bezwe (ukunwebeka kwentambo eyodwa yethusi kumele kube ngaphezu kuka-25%, ububanzi be-monofilament bungaphansi kuka-0.30) ukuqinisekisa ubumnene nokuqina kwe-monofilament yethusi. Ithebula 1 libala izindinganiso okumele zihlangatshezwe ngezinto ezisetshenziswa kakhulu zokuqhuba ithusi.

(2) Izinto zokufaka ungqimba lwezintambo

Indawo yangaphakathi yezimoto zikagesi iyinkimbinkimbi, ekukhetheni izinto zokuvikela ukushisa, ngakolunye uhlangothi, ukuqinisekisa ukusetshenziswa okuphephile kwesendlalelo sokuvikela ukushisa, ngakolunye uhlangothi, ngangokunokwenzeka ukukhetha ukucubungula okulula nezinto ezisetshenziswa kabanzi. Njengamanje, izinto zokuvikela ukushisa ezisetshenziswa kakhulu yi-polyvinyl chloride (PVC),i-polyethylene exhumene (XLPE), irabha ye-silicone, i-thermoplastic elastomer (TPE), njll., kanye nezakhiwo zazo eziyinhloko kuboniswe kuThebula 2.

Phakathi kwazo, i-PVC iqukethe i-lead, kodwa i-RoHS Directive iyakwenqabela ukusetshenziswa kwe-lead, i-mercury, i-cadmium, i-hexvalent chromium, i-polybrominated diphenyl ethers (PBDE) kanye ne-polybrominated biphenyls (PBB) nezinye izinto eziyingozi, ngakho-ke eminyakeni yamuva nje i-PVC ithathelwe indawo yi-XLPE, irabha ye-silicone, i-TPE nezinye izinto ezinobungani nemvelo.

(3) Izinto zokuvala ikhebula

Ingqimba yokuvikela ihlukaniswe izingxenye ezimbili: ungqimba lokuvikela oluhamba kancane kanye nongqimba lokuvikela olulukiwe. Ukumelana kwevolumu kwezinto zokuvikela ezihamba kancane ku-20 ° C kanye no-90 ° C nangemva kokuguga kuyinkomba ebalulekile yobuchwepheshe yokulinganisa izinto zokuvikela, okunquma ngokungaqondile impilo yenkonzo yekhebula elinamandla aphezulu. Izinto zokuvikela ezivamile ezihamba kancane zifaka irabha ye-ethylene-propylene (EPR), i-polyvinyl chloride (PVC), kanyei-polyethylene (PE)izinto ezisekelwe kuzo. Uma izinto zokusetshenziswa zingenanzuzo futhi izinga lekhwalithi lingenakuthuthukiswa esikhathini esifushane, izikhungo zocwaningo lwesayensi kanye nabakhiqizi bezinto zekhebula bagxila ocwaningweni lobuchwepheshe bokucubungula kanye nesilinganiso sefomula sezinto zokuvikela, futhi bafuna ukusungula izinto ezintsha ngesilinganiso sokwakheka kwezinto zokuvikela ukuze kuthuthukiswe ukusebenza kwekhebula.

2. Inqubo yokulungiselela ikhebula le-voltage ephezulu

(1) Ubuchwepheshe bezintambo zomqhubi

Inqubo eyisisekelo yekhebula isithuthukiswe isikhathi eside, ngakho-ke kukhona nemininingwane yazo ejwayelekile embonini nasemabhizinisini. Enqubweni yokudweba ucingo, ngokwendlela yokukhulula ucingo olulodwa, imishini yokubopha ingahlukaniswa ngomshini wokukhulula ukubopha, umshini wokukhulula ukubopha kanye nomshini wokukhulula ukubopha. Ngenxa yokushisa okuphezulu kwe-crystallization yomqhubi wethusi, izinga lokushisa nesikhathi sokunamathela isikhathi eside, kufanelekile ukusebenzisa imishini yomshini wokubopha ukubopha ukudonsa ukudonsa okuqhubekayo kanye nokudonsa okuqhubekayo ukuze kuthuthukiswe izinga lokunwebeka kanye nokuqhekeka kokudweba ucingo. Njengamanje, ikhebula le-polyethylene elixhunywe nge-cross-linked (XLPE) selishintshe ngokuphelele ikhebula lephepha likawoyela phakathi kwamazinga kagesi angu-1 no-500kV. Kunezinqubo ezimbili ezivamile zokwakha umqhubi we-XLPE: ukucindezela okujikelezayo kanye nokusonta ucingo. Ngakolunye uhlangothi, i-core yocingo ingagwema izinga lokushisa eliphezulu kanye nokucindezela okuphezulu epayipini elixhunywe nge-cross-linked ukuze icindezele izinto zayo zokuvikela kanye nezinto zokuvikela esikhaleni sentambo ehlanganisiwe futhi ibangele imfucuza; Ngakolunye uhlangothi, ingavimbela nokungena kwamanzi ngendlela eqondiswe kumqhubi ukuqinisekisa ukusebenza okuphephile kwekhebula. Umqhubi wethusi uqobo lwakhe luyisakhiwo sokugoqa esigxilile, esikhiqizwa kakhulu ngumshini ojwayelekile wokugoqa uhlaka, umshini wokugoqa ifoloko, njll. Uma kuqhathaniswa nenqubo yokuminyana eyindilinga, ingaqinisekisa ukwakheka okuzungezile kokugoqa umqhubi.

(2) Inqubo yokukhiqiza ukufakelwa kwekhebula le-XLPE

Ukuze kukhiqizwe ikhebula le-XLPE elinamandla aphezulu, i-catenary dry cross-linking (CCV) kanye ne-vertical dry cross-linking (VCV) kuyizinqubo ezimbili zokwakha.

(3) Inqubo yokukhipha

Ngaphambilini, abakhiqizi bezintambo babesebenzisa inqubo yesibili yokukhipha izintambo ukukhiqiza i-core insulation core, isinyathelo sokuqala ngesikhathi esifanayo isihlangu somqhubi we-extrusion kanye nesendlalelo sokufaka izintambo, bese sixhunywa bese siboshelwa kuthreyi yezintambo, sibekwe isikhathi esithile bese kuba isihlangu sokufaka izintambo. Phakathi nawo-1970, inqubo yokukhipha izintambo ezintathu enezingqimba ezingu-1+2 yavela enkabeni yentambo efakwe izintambo, okuvumela ukuvikela kwangaphakathi nangaphandle kanye nokufaka izintambo ukuthi kuqedwe ngenqubo eyodwa. Inqubo kuqala ikhipha isihlangu somqhubi, ngemva kwebanga elifushane (2~5m), bese ikhipha isihlangu sokufaka izintambo kanye nokufaka izintambo esihlanguni somqhubi ngesikhathi esifanayo. Kodwa-ke, izindlela ezimbili zokuqala zinezinkinga ezinkulu, ngakho-ke ngasekupheleni kwawo-1990, abahlinzeki bemishini yokukhiqiza izintambo bafaka inqubo yokukhiqiza i-co-extrusion enezingqimba ezintathu, eyayikhipha ukuvikela komqhubi, ukuvikela kanye nokuvikela ngesikhathi esifanayo. Eminyakeni embalwa edlule, amazwe angaphandle nawo aqalise i-extruder barrel head entsha kanye ne-curved mesh plate design, ngokulinganisa ingcindezi yokugeleza kwe-screw head cavity ukuze kuncishiswe ukuqongelela kwezinto, kwandiswe isikhathi sokukhiqiza esiqhubekayo, ukufaka esikhundleni sokushintsha okungapheli kwemininingwane yomklamo wekhanda nakho kungasindisa kakhulu izindleko zesikhathi sokungasebenzi futhi kuthuthukise ukusebenza kahle.

3. Isiphetho

Izimoto ezintsha zamandla zinezinzuzo ezinhle zokuthuthukiswa kanye nemakethe enkulu, zidinga uchungechunge lwemikhiqizo yekhebula le-voltage ephezulu enomthamo ophezulu womthwalo, ukumelana nokushisa okuphezulu, umphumela wokuvikela kagesi, ukumelana nokugoba, ukuguquguquka, impilo yokusebenza isikhathi eside kanye nokunye ukusebenza okuhle kakhulu ekukhiqizweni nasekuthatheni imakethe. Izinto zekhebula le-voltage ephezulu yemoto kagesi kanye nenqubo yokulungiselela kwayo zinamathuba abanzi okuthuthukiswa. Imoto kagesi ayikwazi ukuthuthukisa ukusebenza kahle kokukhiqiza futhi iqinisekise ukusetshenziswa kokuphepha ngaphandle kwekhebula le-voltage ephezulu.

Isikhathi sokuthunyelwe: Agasti-23-2024